The Science Behind Thermal Sensors: How They Work

Temperature Measurement Demystified

At the core of our understanding of thermal sensors is temperature measurement a fundamental concept in science and engineering. Temperature is the measure of thermal energy within a given system, influencing various physical and chemical properties of materials. It has profound implications in different fields, including engineering, healthcare, and environmental science. Thermal sensors operate on the principle of converting thermal energy into measurable electrical signals, allowing for accurate temperature readings that are vital for monitoring and control systems. Thermodynamics and heat transfer govern their functioning, marking them as pivotal instruments in both industrial and consumer applications.

Thermal sensors can be broadly categorized based on how they measure temperature: contact and non-contact sensors. Contact sensors, like thermocouples and resistance temperature detectors (RTDs), require direct contact with the substance they measure. In contrast, non-contact sensors, such as infrared thermometers, detect temperature by capturing the infrared radiation emitted from an object. This fundamental differentiation significantly impacts their application, efficiency, and response time, showcasing the need for precise selection based on the context of usage.

The Role of Thermocouples and RTDs

Thermocouples and Resistance Temperature Detectors (RTDs) are two primary types of contact thermal sensors recognized for their reliability and effectiveness. Thermocouples consist of two different conductive materials joined at one end. When the junction experiences a temperature change, it generates a voltage that can be correlated to the temperature difference. Their wide temperature range, exceptional durability, and rapid response make them the preferred choice in extreme environments, such as in industrial processing and aerospace applications.

On the other hand, RTDs operate based on the principle that a material’s electrical resistance varies with temperature. Typically made of pure metals, RTDs offer superior accuracy and repeatability compared to thermocouples, albeit at a higher cost and slower response time. The versatility of RTDs makes them suitable for a broad range of applications, including food processing, HVAC systems, and laboratory experiments. Both devices exemplify how different mechanisms can achieve similar objectives, yet their suitability will depend on specific operational requirements temperature range, environment, and accuracy.

Understanding Infrared Sensors and Their Unique Capabilities

Infrared (IR) sensors represent a fascinating advancement in thermal sensor technology. These non-contact sensors measure temperature by detecting the infrared radiation that objects emit as a function of their thermal energy. This approach allows for safe and instant temperature readings from a distance, which is particularly invaluable in situations where traditional sensors would pose risks, such as in hazardous environments or for moving objects.

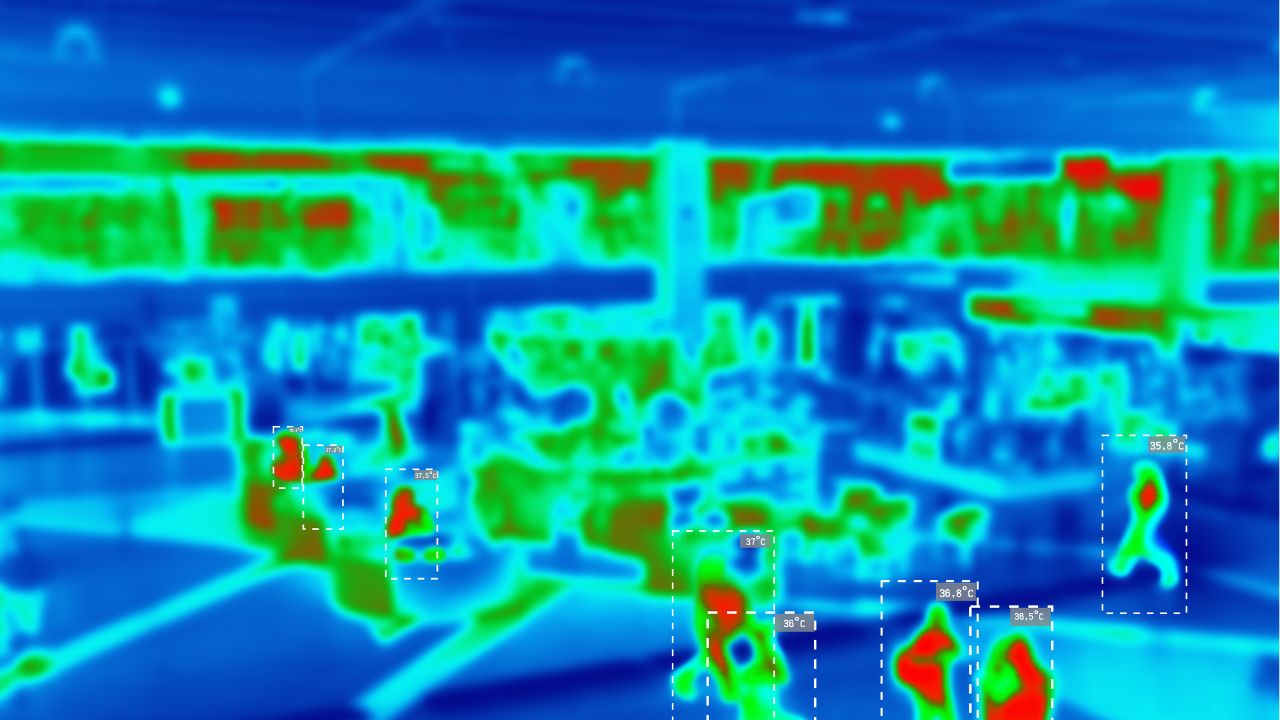

IR sensors extend beyond simple measurements; they harness sophisticated algorithms and optical systems to differentiate between various temperature profiles, enabling the operator to detect hotspots or temperature anomalies promptly. Applications in fields such as firefighting, electrical engineering, and medical diagnostics demonstrate their versatility. For instance, spotting an overheating electrical component before a system failure can prevent costly downtimes or accidents, while in healthcare, they can facilitate the quick assessment of body temperatures, crucial in managing infectious diseases.

Innovative Applications of Thermal Sensors Across Industries

From Automotive to Aerospace: A Thermal Revolution

The automotive industry is undergoing a dramatic transformation driven by advances in thermal sensing technology. With the inception of electric vehicles (EVs) and autonomous driving systems, ensuring optimal thermal management has become paramount. Thermal sensors monitor battery temperatures, preventing overheating and maximizing efficiency to enhance both safety and performance. The synergy between thermal sensors and battery management systems is central to extending the lifespan of lithium-ion batteries, correcting thermal imbalances, and optimizing charging cycles.

Equally pertinent, the aerospace sector employs thermal sensors for a plethora of applications including engine monitoring, structural health assessments, and environmental control systems in aircraft. The ability to maintain precise temperature metrics during flight operations is essential, considering the drastic temperature fluctuations experienced at high altitudes. Advanced thermal sensors are integrated into systems to ensure that safety thresholds are not breached, thus reinforcing the reliability and performance of modern aircraft.

Healthcare Innovations: Monitoring and Diagnostics

Healthcare has witnessed a significant infusion of thermal sensor technology, fundamentally reshaping patient monitoring and diagnostic practices. Continuous temperature monitoring is critical in determining fever thresholds and managing infectious diseases, while IR thermometers have transformed the efficiency of measuring body temperatures in clinical settings. The COVID-19 pandemic catalyzed the widespread adoption of non-contact thermal sensors in hospitals and public spaces, showcasing their ability to rapidly screen individuals for elevated temperatures.

Moreover, wearable thermal sensors have emerged as game-changers in personalized health tracking, allowing for continuous assessment of vital signs and enabling data-driven interventions. The integration of these sensors in home healthcare devices is not only improving patient outcomes but also facilitating remote health monitoring, thereby significantly reducing the burden on healthcare systems. As more sophisticated technology enters the fray, the potential for thermal sensors in diagnostics and real-time patient monitoring continues to expand, promising innovations that were once the domain of futuristic fiction.

Smart Homes and IoT: The Future of Temperature Control

As smart home technology proliferates, thermal sensors have become an integral part of Internet of Things (IoT) ecosystems. These sensors drive energy efficiency by enabling smart thermostats to optimize heating and cooling systems based on real-time temperature readings. Homeowners can achieve significant cost savings and enhance comfort levels through automatic adjustments that respond to fluctuations in indoor and outdoor temperatures.

Additionally, thermal sensors in security systems enhance safety by detecting changes in temperature that may indicate fires or unauthorized access. By integrating with smart home platforms, these sensors offer an unprecedented level of control and insight, allowing users to monitor their environments through mobile applications. As smart technologies evolve, the intersection of thermal sensing and IoT will likely lead to even more refined home automation systems, personalized climate control, and enhanced energy management strategies.

Choosing the Right Thermal Sensor for Your Needs

Key Factors to Consider for Optimal Performance

Selecting the appropriate thermal sensor for a specific application necessitates careful consideration of several factors. The first aspect to evaluate is the operational environment, as conditions such as humidity, electromagnetic interference, and potential exposure to corrosive substances can affect sensor performance and longevity. For instance, a high-precision RTD might be indispensable in laboratory environments, while a rugged thermocouple may be better suited for high-temperature industrial processes.

Moreover, one must consider the required temperature range and the precision level indispensable for the application’s success. Different sensors have varying ranges with certain models optimized for extreme temperatures, while others excel in standard ranges. Additionally, resolution and accuracy are paramount often expressed in terms of Linear Measurement Accuracy (LMA) which details how accurately a sensor can measure a given temperature. Taking into account these technical specifications ensures that the thermal sensor will deliver reliable results, thus fulfilling operational requirements efficiently.

Comparative Analysis: Passive vs. Active Sensors

In the realm of thermal sensors, a fundamental distinction exists between passive and active sensors. Passive sensors, such as thermistors, generate signals based solely on their ambient temperature, making them typically less complex and cost-effective. Their simplicity, however, can impose limitations on their responsiveness and operational ranges. In contrast, active sensors, like thermocouples and infrared sensors, actively generate voltage or signal output in response to temperature changes, allowing for quicker response times and broader application scopes.

When choosing between passive and active sensors, considerations include the required responsiveness, accuracy, and environmental constraints. Active sensors are ideal for more complex applications demanding rapid and precise measurements, while passive sensors can suffice in simpler scenarios. Ultimately, understanding the operational demands and financial constraints will guide one towards the appropriate selection between passive and active thermal sensors.

Expert Tips for Sensor Calibration and Maintenance

The performance of thermal sensors hinges largely on appropriate calibration and maintenance practices. Sensor calibration ensures that the device is providing accurate measurements and is typically performed in controlled environments with reference standards. It is essential to regularly calibrate sensors against known temperature references, particularly in critical applications such as healthcare or aerospace, where even slight discrepancies could lead to significant consequences.

Moreover, maintaining thermal sensors encompasses both physical and operational care. This includes protecting sensors from potential contaminants, handling them carefully during installation to avoid damage, and ensuring they are appropriately housed in protective casings, especially in harsh environments. Regularly scheduled assessments and checks, as well as logging performance data, can help in early detection of potential issues. By establishing a robust calibration and maintenance regime, organizations can enhance the lifespan and accuracy of their thermal sensors, ensuring optimal operational efficiency.

Challenges and Future Trends in Thermal Sensing Technology

Addressing Accuracy and Sensitivity Challenges

As thermal sensing technology evolves, accuracy and sensitivity remain paramount challenges that researchers and engineers must navigate. Environmental factors, electromagnetic interference, and the physical characteristics of the materials being measured can all introduce variability in sensor performance. The need for extreme precision is particularly critical in fields like medical diagnostics and industrial automation, where slight variances can yield significant repercussions.

Advancements in materials science and engineering aim to develop sensors with enhanced sensitivity and robustness. Research is increasingly focusing on nanomaterials and innovative designs that can improve the response times and range of thermal sensors. Moreover, the deployment of machine learning algorithms to process and analyze sensor data can enable more accurate interpretations and compensations for environmental discrepancies, pioneering steps toward smarter thermal sensing solutions.

The Rise of Nanotechnology in Thermal Sensors

Nanotechnology represents an exciting frontier in thermal sensor development. At the nanoscale, materials exhibit unique thermal properties that can be leveraged to create highly sensitive and responsive sensors. By incorporating nanostructured materials in sensor designs, manufacturers are able to enhance the thermal conductivity and sensitivity, thus ensuring precise measurements even in challenging environments.

Innovations such as graphene-based thermal sensors are emerging due to their remarkable conductivity and strength. These sensors can be engineered to respond to minor temperature variations, which proves beneficial in applications requiring high accuracy, such as micro-electromechanical systems (MEMS) and biomedical diagnostics. As research continues to uncover the vast potential of nanotechnology in thermal sensing, we can expect a revolutionary shift towards more effective, compact, and reliable thermal sensor solutions.

What’s Next? AI Integration and Smart Thermal Solutions

The future of thermal sensing is increasingly intertwined with artificial intelligence (AI) and data analytics, paving the way for smart thermal solutions. By integrating AI algorithms into thermal sensor systems, real-time data analysis and predictive modeling can be achieved, allowing for proactive maintenance and innovative applications. For example, the convergence of AI and IoT thermal sensors in smart buildings can facilitate energy-efficient climate control systems, optimizing energy consumption based on real-time data.

Additionally, as the technology matures, we will witness the advent of predictive analytics that can lead to not only better temperature monitoring but also the prevention of potential malfunctions or safety hazards. This shift emphasizes a movement towards intelligent systems that not only react to temperature changes but anticipate them, revolutionizing entire industries from manufacturing to healthcare. As these technologies converge, the implications for safety, efficiency, and innovation are profound and offer a tantalizing glimpse into the future of thermal sensors.