Now if your screen is locked with Android iPhone password, Android iPhone PIN, Android iPhone pattern and Android iPhone fingerprint. iSkysoft removes all of them, yet keeps all data complete. It will not access, to modify, or terminate anything in your device – your data and privacy are 100% safe.

Obviously, you can open android lock screen removal by re-configuring your phone hardly, but you should know that the entire factory reset on devices means clearing any data. Just this means that it will take your Android phone into the same condition as it will reach the box. It will be good to avoid losing data, if you can pass the Android lock screen without resetting. You’ll also have to wonder how to bind the Android lock screen without reset, so, in this guide, we remove you from an easy-to-use Android screen lock with iSkysoft tools that can help you make any effort to resolve it.

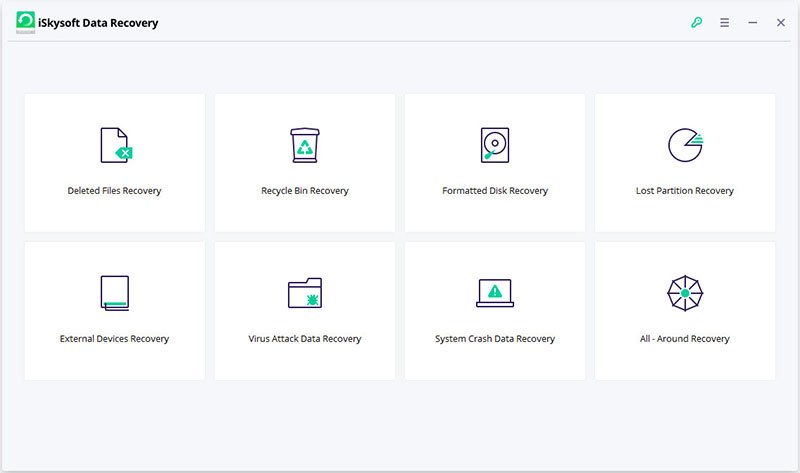

Designed as Android and iOS data, iSkysoft has helped millions of users get their lost data back easily. At the same time, this is also the ability to solve even more troublesome problems, such as iSkysoft for Android, you can re-reset the screen patterns, fingerprints, or passwords on your Android device and loss of data Removal can be helpful. More than anything, this function is completely free for you.

With just a few clicks, you can bypass the Android lock screen without comfortable. Now, download iSkysoft for Android.

Unlock iPhone with iSkysoft

When you forget the password of your smartphone and think about that how to unlock iPhone for personal working so that don’t worry iSkysoft solve the issue lock of iPhon android. Of course, you have passed this situation and you should know. How often did you have your Android smartphone, but one of your sons, nephews, younger brothers, or your parents, who wanted to love your Android phone and in their efforts because the lock screen stopped it. The problem is that the fate was trying to put their pattern more than five times the blocks. Sure, it is possible that by chance, we are very confused and we have locked ourselves.

First, there is no need to panic, because we’ll see how to leave the lock and access your Android or phone tablet. But in all ways, whether a terminal-based protection system has a PIN or password, and does not have a pattern or face recognition, almost certainly will definitely lose all data processing. You should make up till now.

If you have more than 5 attempts, there are several ways to unlock your screen. So there is don’t worry about the solution. There are two ways to unlock the password on the Android phone.

Screen Password Unlock with Google Account

As a way blocked pattern allows us to enter wrong drawings for five times and leave the holiday. If we try to try, we get a message that we have to wait for 30 seconds. If you still do not encourage the divine, we have to recognize that we have forgotten. To do this, “Forgot the pattern?” Click on Once you leave us a screen where we enter our data into a GMM account. You are allowed to open your device lock using your Google Account identifications.

1) After lock-in pattern, the screen will be locked.

2) When lock your iPhone screen, you “forgot the pattern?” You can click on

3) Enter the username and password for your Google Account. (Assume that you have signed a Google Account)

4) Click on the “Sign in” tab

5) It allows you to drive a new unlocking pattern.

This method you need to connect to your device to the Internet (Wi-Fi) or you cannot log in to a Google Account.

After unlocking the phone successfully, it is very important that you often have to use a record of important passwords that you often use. There are many password manager apps that make it very easy to save and read passwords in one place. You can find some amazing apps for this purpose from the iPhone Password website.

Factory Settings Restore to Remove Password

If the said key does not work for you, unluckily, you will have to plan to take dangerous measures. I’m talking about a hard change, or is that – repair the factory settings. It’s a tough but effective way.

Take gradually to reset the factory setting to your Android device.

1) In first step, you take power from your device, then push the hold the key press down the key and the power / lock key for a few seconds. This will wrap your device. Then you will enter the recovery mode.

2) Navigation using key just below the volume. Go to on the option of “wipe data / wipe factory setting reset”, kill it. Now your device data and setting all will be wiping. Now when you restart your iPhone and by using of iSkysoft your password will be removed.

Screen/PIN Remove Password without Losing Any Data

If you do not have a Google Account and want to keep all data on the phone, you should use iSkysoft. The password removal tool is embedded in the program and you can remove a PIN / pattern / fingerprint password in a few minutes. Most importantly, there is no data loss using this method.

So the easiest way to reset the screen password is with Google Account. If you do not have any passwords, please still make the use of more. Another thing to note, Android Data Recovery is also the iSkysoft Internal Memory and SD card. This is the most powerful tool for Android users.