The modern era of technology has undeniably transformed the conventional ways of storing massive data. The latest storage media such as hard drives and flash storage drives are capable of storing huge data without compromising on performance. Let’s proceed to know the top things to know before picking a hard drive.

There’s always a dilemma while choosing an appropriate hard drive for business as well as personal requirements. One needs to understand the basic difference in a Solid State Drive and a hard drive.

5 Indispensable Things to Keep in Mind while Picking a Hard Drive

In this article, we’ll be discussing some aspects that one must consider while picking a hard drive.

Analyze your Requirements

If you are looking a hard drive for a computer system that you need for personal work, you must think about a disk drive instead of a Solid State Drive. In general, people do not have an idea about the basic difference between both the drives.

SSD (Solid State Drive) vs. Hard Drive

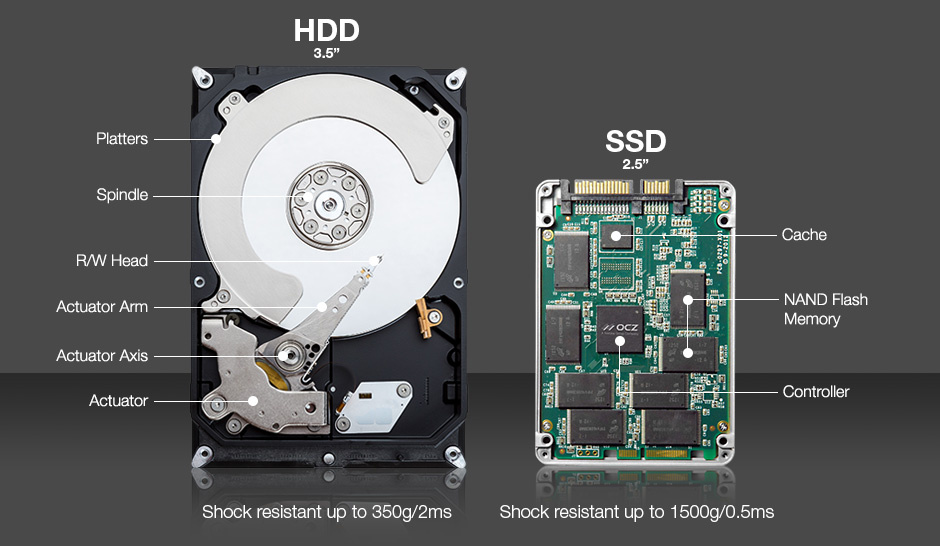

An SSD is superior storage media based on flash storage, which is comparatively fast than a hard disk. There are no rotating disks or moving parts on an SSD drive and is smaller and compact. Moreover, hard drive data wiping is faster in SSD as compared to HDD.

Read also: How To Securely Wipe Your Confidential Data From A Hard Drive

A hard drive, on the other hand, has moving parts and takes a lot of space in your system. Furthermore, a hard drive is many times slower than flash storage media.

Physical Size

Well, after you’ve got an idea regarding the basic difference between SSD and hard drive, the next thing is to choose the right size. You need not worry as there are only two sizes available. One is the 3.5-inch drive, and the other one is the 2.5-inch drive.

The traditional disk drive contains a spinning mechanism that requires more space. The desktop hard drives are usually of 3.5-inch size with a maximum of 4TB space, whereas the laptop hard drives are of 2.5-inch with a maximum of 2TB storage. The size of the disk depends upon the number of disks in the drive.

Interface

The interface of a hard drive is usually a SATA connector for both SDD and HDD. There may be some portable hard drives that are connected through USB but can’t be used for a permanent drive on a laptop of the computer.

Furthermore, one should ensure the interface of the hard drive matches their laptop or computer’s hardware specification.

Performance

People seeking a storage media for their business purposes must consider a flash storage drive instead of a conventional hard disk drive. An SSD drive delivers outstanding performance and has lesser downtime as compared to the regular disk drives.

These drives are available in the same storage options as that of the conventional drives. You can choose the one according to your requirements. The primary benefit of an SSD drive is that it can deliver superior data transfer rate that you can’t expect from a hard disk. It is an ideal option for businesses that rely on massive storage of data.

Internal or External

Another important aspect to consider is the need for a hard drive. Sometimes people often get confused between picking a portable hard drive and an internal hard drive of a computer.

If you are seeking a hard drive that can store your additional data apart from the system, you should think about a portable hard drive. A portable hard drive can be connected to your system’s USB port.

Conclusion

One should be very precise while picking a hard drive for their business use. There are numerous options available in the flash storage drives that can offer superior performance.