Waterjet and laser cutters can slice through materials that no other cutting tool can. They are invaluable for prototyping products and precision manufacturing. But which one is worth the hype – waterjets or laser cutters? This article provides everything you need to know about waterjet vs laser cutting units. Learn how they work and which one is best for your industrial manufacturing facility.

Waterjet Vs Laser Cutting:

Unlike the vast majority of blades and saws, waterjets and laser cutters don’t have a blade. The lack of a blade makes engraving and detail work much more precise. And, waterjets and laser cutters are computer operated, as to achieve a very high level of precision.

Both machines can engrave minute lettering and symbology into a wide range of manufacturing materials. But each machine goes about it a very different way.

Both methods of cutting excel with 2D objects and engraving, but which is better: waterjet or laser cutting?

What Is Laser Cutting?

Laser cutting uses a high-focus laser to cut or engrave materials. Laser cutting is a method of subtractive manufacturing, which means it only takes away material.

This is in opposition to additive manufacturing, like 3D printing.

Special software guides the lasers using mirrors. A gas power source provides energy to the system, usually in the form of CO2. The CO2 fuels the laser which outputs between 1,500 and 2,600 watts.

Some systems implement an additional gas jet to expel the excess material.

Laser cutting is a very precise form of subtractive manufacturing. The intense heat of the laser cuts through material like a razor using a precision burn. Laser systems cut material from sheets or large panels.

Laser Cutter Materials:

Laser cutting systems make precision cuts in a wide range of materials. The only material that a laser cutter is not “cut-out” for is reflective metals. The reflective property of some metal reflects the laser off of the cutting surface, which can be dangerous.

Laser cutters are great for cutting glass, wood, plastic, and a wide range of metals.

Laser cutters encounter obstacles, however, when trying to cut compound materials. If the material contains multiple materials, then it has multiple melting points. If the material has multiple melting points, then a laser takes longer to cut through it, and cuts can become uneven.

Laser cutting systems work the best with flat sheets of material, with a thickness range between 0.1 inches to just under a half-inch.

And, most laser cutting systems proficiently perform the functions of cutting, drilling, engraving, welding, ablating, and structuring.

What Is Waterjet Cutting?

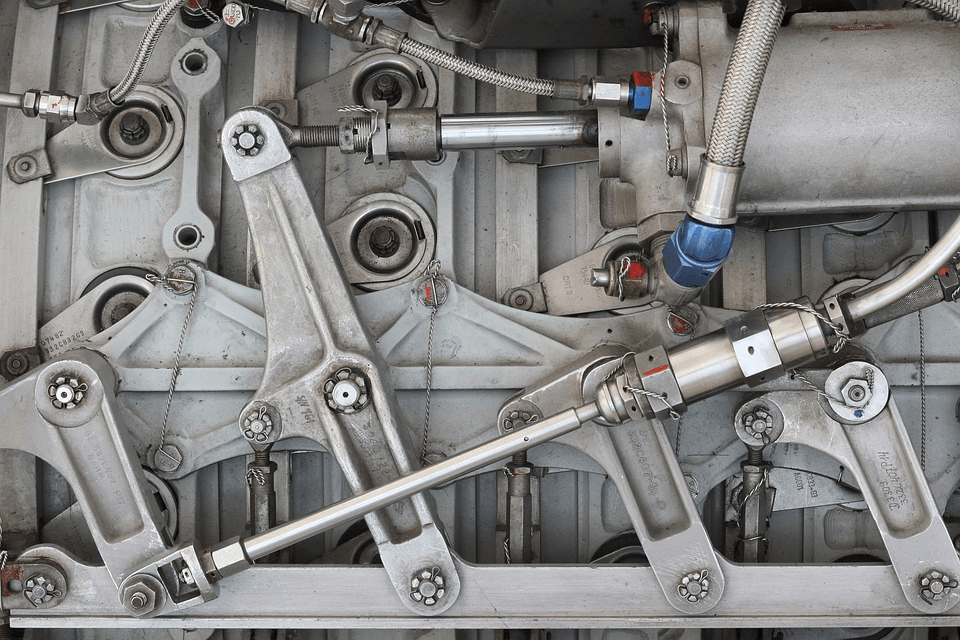

Waterjet cutting systems utilize a high-pressure waterjet to slice through materials. The water is shot through a very fine point and creates over 60,000 pounds of pressure per square inch.

For tougher materials, a mixture of water and an abrasive acts like a diamond saw blade.

Garnet is a common abrasive for use in waterjet cutters. Aluminum oxide is another common abrasive that you can use with a waterjet cutter.

The process of waterjet cutting is a high-speed version of natural erosion. With a big enough waterjet cutter, you can make another grand canyon in a fraction of the time. Read more about how the best water jets can cut through anything nature makes.

Waterjet cutters differ from laser cutters in that the power source does not reside with the cutting unit. Since a waterjet cutter outputs between 4 to 7 kilowatts, the water pump is located away from the worksite. This is also true because the water source is rarely nearby your bench.

Waterjet Cutting Materials:

Unlike a laser cutter, waterjet cutters can effectively cut almost any material. They have no problem cutting through compound materials with multiple material types. The pure pressure of the water jet is enough to cut cleanly through anything.

Waterjet cutter units are especially useful for cutting precisely through masonry. They’re also good for cutting and structuring stone, thick metals, ceramics, and glass.

Waterjets handle thicker material than laser cutters. They can handle material that is up to around 2 inches thick. But they don’t do as well with material thinner than 0.4 inches.

Level of Waste from Waterjet vs Laser Cutting:

Laser cutters create a minimal amount of off-fall and waste. Very little, if any, cleanup is required after cutting. The only waste that laser cutting produces is a small amount of dust that is easily vacuumed up.

Waterjet cutting, on the other hand, creates a lot of waste. You might think that waterjet cutting would be cleaner, but it is not. The abrasive material in the water adds a toxic element to the off-fall liquid.

For this reason, waterjet cutting requires special waste-water disposal, safety gear, and a bigger project budget.

What’s the Cost to Purchase and Operate a Waterjet vs Laser Cutter?

A plasma laser cutting machine will cost between $15,000 to over $250,000 at the initial purchase. Waterjet cutters are more expensive because they require more specialized materials. They range from $100,000 to around $400,000.

On average, either machine will cost around $350k. Expensive industrial machines can exceed $1,000,000.

On average, a laser cutter costs between $13 to $20 an hour to operate. Waterjet cutting systems run between $15 to $30 an hour to operate.

Final Thoughts:

At the end of the day, waterjet cutters cost up to five times more to operate than laser cutters. Waterjet cutters can cut thicker and more complex materials, but they are slower than laser cutters. So, when considering waterjet vs laser cutting, laser cutting will save you time and money.

If you like this article on which is better, share it with your friends on social media. And check out the blog for more resources on hardware and gadgets. Thanks for reading!

Read Also: