Several industries that produce liquid products, such as pharmaceuticals, food & beverage, agriculture, etc., rely on bottle capping machines to complete their production processes. Most bottle cappers in the market are designed to be as versatile as possible, allowing companies to reuse these machines for a wide range of compatible capping operations.

Bottle capping machines can be grouped into either of the three categories: manual, semi-automatic, and fully automatic. Beyond this classification is another distinction, based mainly on the mode of operation and design. Under the second classification, we have three types of cappers: inline cappers, chuck cappers, and rotary cappers.

Most bottle cappers in the market are either semi-automatic or fully automatic. The latter is more efficient, plus they come with more equipment parts. They are also more flexible and easy to work with, hence, suitable for medium to large scale production. The semi-automatic models require some human input and are best suited for small to medium-scale production.

The Bottle Capping Process

Capping is the process of sealing or covering a bottle/container with a lid. Different capping machines use other mechanisms to place and tighten the caps on containers. This often depends on the production speed, the type of containers/bottles being used, and the nature of the product.

Inline bottle cappers, for instance, can handle up to over 300 caps per minute and are best used for small to medium businesses that require medium production speeds, such as milk, soda, and beer.

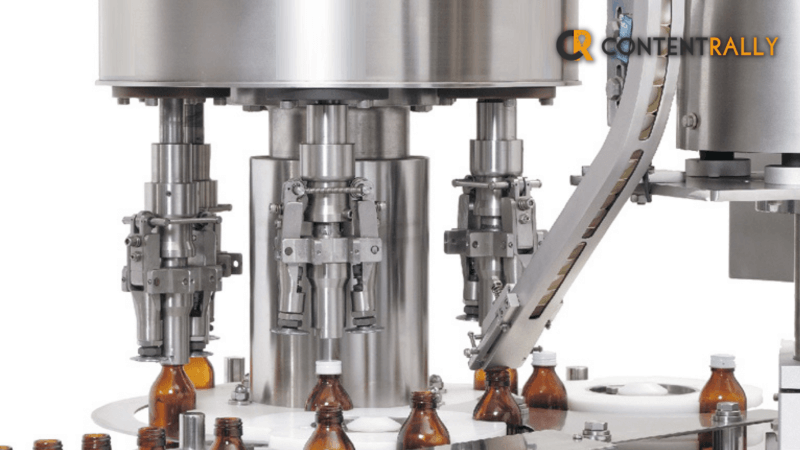

That said, a fully automatic bottle capping machine will have several components to ensure accurate sorting of the caps, placing, and tightening. To understand how the capping process works, we will use an inline bottle capper for illustration. The latter is designed to work in line with the other production processes; hence they should be reliable and accurate. Here are the common parts of a bottle capping machine and their role throughout the capping process.

* Loading Hopper

A loading hopper holds many caps and directs them to the cap sorter. The design of the loading hopper depends on the caps’ size and the type of the capping machine.

* Cap sorter

As the name suggests, this equipment’s work is to choose the right cap for the right bottle and allow only one cap to exit the sorting platform at a time. Different cap sorters have varying mechanisms of operation. One popular technique is using a mechanical rotating disk that accurately selects one cap for a specific bottle/container.

* Cap Chute and Chute End

The cap chute guides the cap from the sorting platform to the part where it’s placed on top of the bottle. Inline cappers have cap chutes specially designed to enhance this sorting operation. Similarly, chuck and rotary cappers are designed to sort and pick the right caps for placement.

On the other hand, the chute end allows only one cap to be released and placed on top of the container. Some of the best bottle capping machines provide a quick changeover of the chute ends to allow for flexible operations with different bottle sizes and cap designs.

* Quill or Chuck

A chuck or quill is responsible for applying some force on the cap such that it turns and tightens the bottle. There are various designs of chucks depending on the size and design of the cap and bottle.

* Gripper

A gripper works by holding the bottle in place as the cap is applied. The gripper’s material, design, and working principle vary depending on the container’s size, design, and fragility.

Choosing a Bottle Capper

When choosing a bottle capper, there are a couple of factors to consider. First, you want to pay attention to your cap & container design, material, and applications. Similarly, you should consider the current and future production needs before picking either a semi-automatic or fully-automatic capper. The other aspects to pay attention to are largely the design features of the capping machine.

For instance, you want to choose a heavy-duty material that’s reliable and durable. Versatility is another vital feature that allows you to swap bottles and caps without changing the major machine parts. This feature also comes in when choosing the production speed of the machine.

Ideally, it’s recommended to pick a bottle capping machine that uses a servo motor instead of the traditional and less-flexible belt box. This is because you can conveniently adjust the torque and speed controls for different applications with servo motors.

In specific industries such as pharma and food & beverage, clean-in-place (CIP) technology is a critical feature that minimizes the chances of contamination. That said, always refer to specific industry compliance specifications before choosing a bottle capper.

Last but not least, you should choose a bottle capper with a simple design. For instance, the moving parts must be easily accessible and, where possible, visible. This makes it easy to spot defects or potential issues that lead to serious downtimes.

Get Started Today

A bottle capping machine is a great addition to your overall production process. Understanding the various components of this machine allows you to choose the right product that will meet your unique production needs. For the best results, choose to work with a reputed manufacturer with a proven track record in the industry.

Read Also: