We all are aware of the natural gas which is been used from last 19th-century consist of the methane and the naturally occurring hydrocarbon gas. All the gases that are present in the natural gas are naturally present in the atmosphere, after that it is converted into the usable form.

There are several uses of the natural gas which we will discuss in this blog, so, just check out the information below:

5 Uses of Natural Gas:

It can be used for the heating purpose:

Firstly natural gas can be used for heating purposes in cold regions. In the region like America, natural gas is used for the purpose of the heating and its produced heat is warmer than the electrical pump.

Used as the fuel:

You must have seen vehicles that are operated by the CNG or compressed natural gas which is the compressed form of the natural gas. This can also be used as a coolant in the air conditioners so, that they can easily work efficiently. This is very much cheap as compared to the diesel as well as petrol.

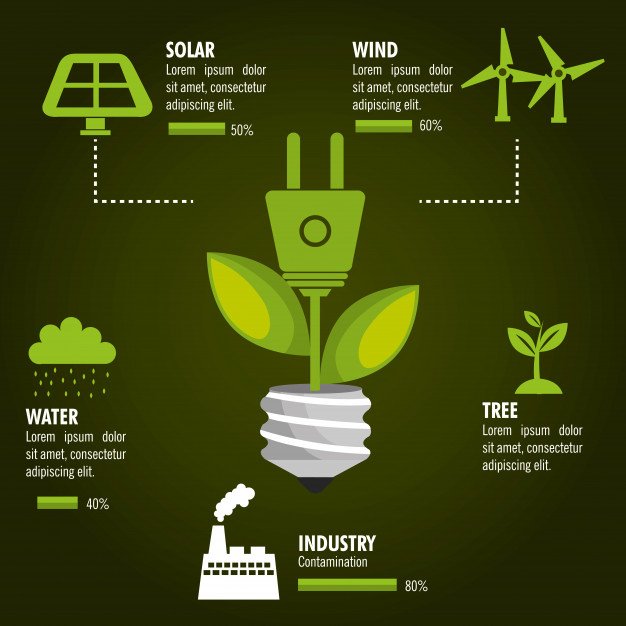

For producing electricity:

Mainly, the natural gas is used for producing electricity and in the United States, around 25% of the population is having power supply generated by the natural gas. Moreover, the usage of natural gas is not as much harm to the atmosphere.

It can use for the purpose of cooling:

There are many air-conditioned units that are made by the natural gas, but on the other hand, this process is pretty much costly. Through, this the customers can easily save their electricity bills and can reduce the maintenance cost.

It can use for the purpose of drying clothes:

Last but not the least natural gas can also be used for drying clothes. If we talk about the advantage of using the natural gas for drying clothes then they can save a lot of energy as compared to the electric appliances. If we talk about the storage then they are relatively easy to store and they can be easily transferred or taken from one place to the other with the help of the pipelines and the services providers who deal in providing such services are known as the Energy Assessment Services provider.

What are the various advantages of Natural Gas?

- As we have already discussed that natural gas is not harmful to the environment as compared to coal and petroleum.

- The presence of the natural gas is more as that of the coal and the petroleum.

- The usage of the natural gas is completely safe as this is lighter than the air.

- The usage of the natural gas provides instant energy which means that there is no pre-heating required prior using this. This is the reason why the natural gas is used in microwaves Owens.

Although, besides all these uses; the natural gas is also used for the industrial as well as commercial purposes. For availing all the benefits you must have the best Natural Gas Products that you can easily get from the online store or offline store.

Read Also: