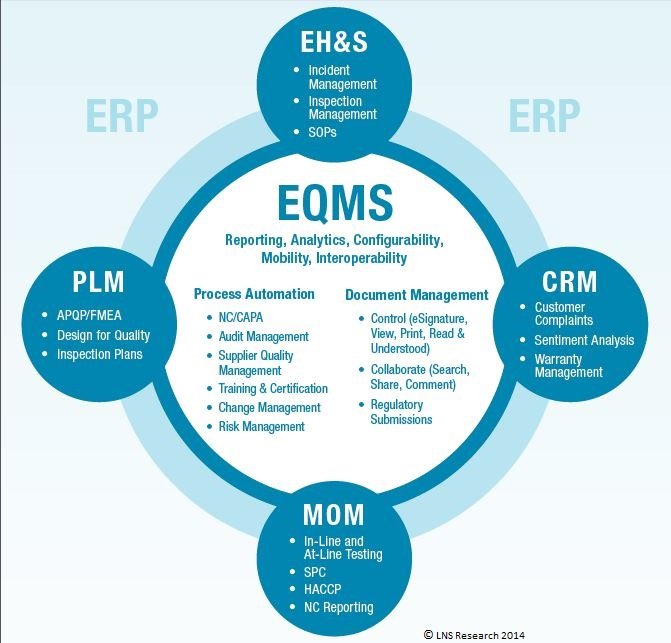

EQMS solution is an emerging enterprise software category that manages business processes and content for compliance and quality across the value chain system. You can view it as a high-quality management podium with an integrated data model and IT design that facilitates collaboration and cross-functional communication. While the general management systems and practices behind the management of quality have remained to be consistent for several decades, the methods and solutions used to ensure the production and delivery of high-quality products and processes across the value chain have changed considerably. With modern technological developments, there is a shift towards organizations implementing point quality solutions most of them quality-specific and home-grown modules in ERP systems to manage quality. With the market need, there has been the emergence of a new software category, EQMS (Enterprise Quality Management Software).

How To Choose The Right EQMS Solution?

Below are things to consider when choosing the right EQMS:

Understand The Type Of EQMS Solution Providers You Need For Quality Management:

Due to the increasingly globalizing and competitive economy, there’s the need for more integrated and better compliance, quality, and risk processes on the value chain system. The EQMS market has continued to mature together with these needs, and companies now have a variety of alternatives for achieving them. Thus one needs to know what is right for their organizations. If you highly focus on manufacturing or engineering, PLM-based or MOM-based EQMS may be the best option you have. If you are leveraging the use of contract manufacturers and suppliers, and wish to get visibility into upstream operations, ERP-based or PLM-based EQMS may still be the best way forward. If it’s engineering or manufacturing, it may make a lot of sense to choose a MOM-based or PLM-based EQMS. If it is a corporate quality control system, ERP-based or stand-alone EQMS may be the best option at your disposal.

Find Out Where Your Focus Is, Either Compliance And Risk Or Driving Business Value And Product Quality:

In case your organization is highly regulated, or you run asset-intensive industries you should aim at taking a positive approach to compliance and risk with EQMS functionalities. If business value and product quality are your motives for quality implementation, products like ETQ Reliance QMS software offer an extensive catalog of options to ease this practice.

Identify Your Current Maturity Look Like And IT Footprint And Understand The Projects You Are Already Investing In:

It is common for a company to make IT-related investments that promote its principal competency. If your company is in the middle of an ERP exploitation, ERP-based EQMS should get special consideration. If your company generates most of its value through its production effort and design, then you are likely to have a significant MOM or PLM footprint already in place. In this case, extending EQMS through these platforms will be the most cost-effective. If you are not pouring a high level of resources into the current system, then the value that stand-alone EQMS provides may be easily justifiable.

The Budget And Speed Needed For Implementation:

Knowing how much money you need and the specific time to solution value will play a significant role in your solution approach as the valuation time has a tight connection to the current IT investments. Most stand-alone EQMS providers have a leg up in this area, but there are some ERP, MOM, or PLM vendors today who are looking towards expanding quality capabilities and willing to remain flexible with new clients in the industry.

Your Quality Vision:

As you determine the best solution approach for your business, it is critical to think about your long-run quality vision. That is, don’t continue on this path and make an investment to fill a need. Instead, do your due carefulness and invest in a scalable IT solution that continues to deliver cross-functional value with time.

Conclusion:

Determining your solution approach is critical only if you find the correct vendors that could fill your needs bearing in mind the above considerations.

Read Also:

- 6 Software Technologies That Will Dominate 2018

- Riding The Wave Of Popularity: 7 Most Popular IT Buzzwords And What They Really Mean

Featured Image: lnsresearch.com