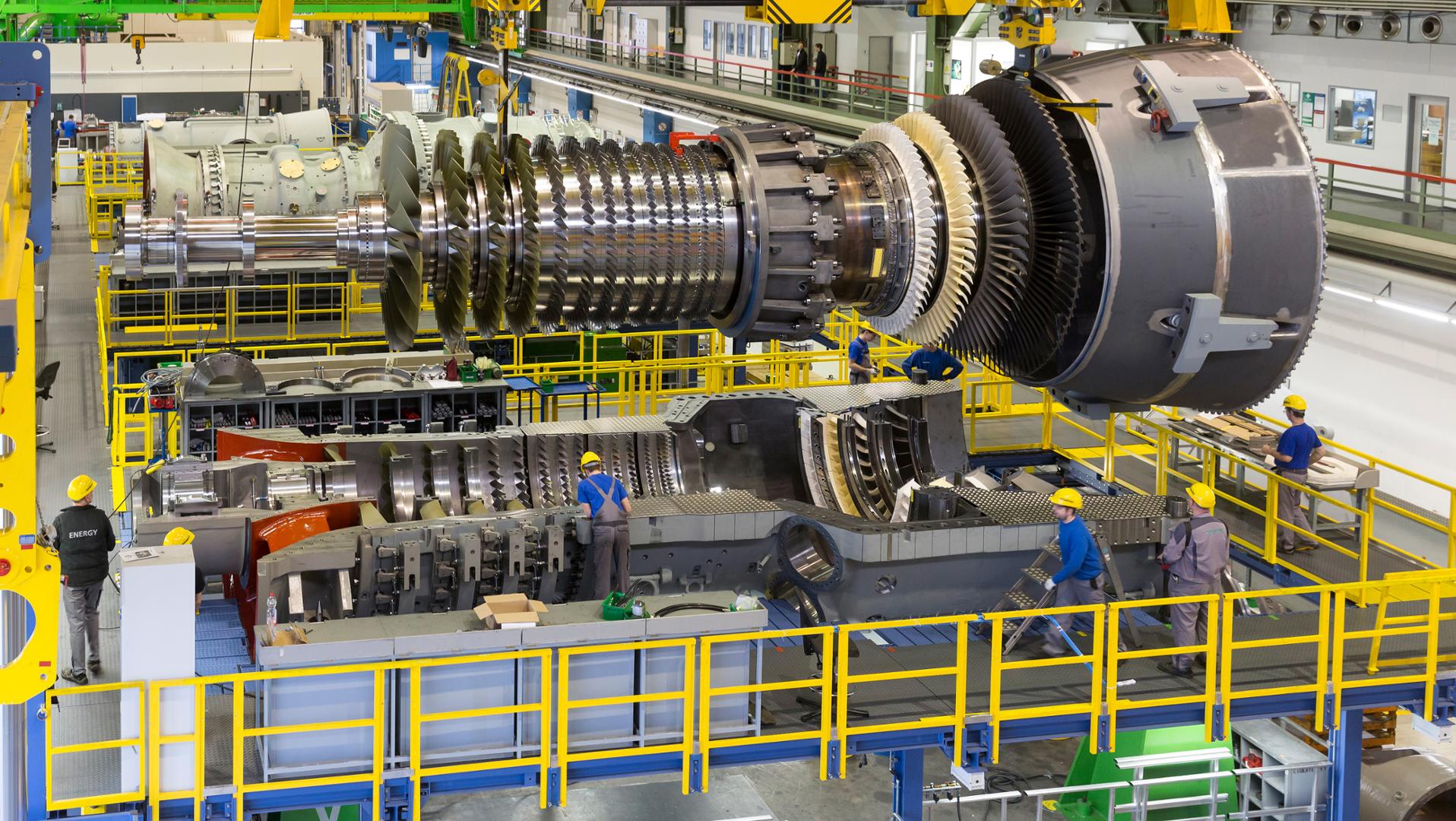

Modern gas turbines are made to put out more power and operate with better efficiency than previous generations. Many major manufacturers of turbines, like GE and Siemens, have reached an efficiency of around 65%. Making sure gas turbines are running at that high level of efficiency is not an easy task, and it takes a lot of maintenance. Taking a top tier approach is necessary for this process, especially since equipment operates at a much higher temperature than before and but far more stress on the turbine, which will ultimately lead to performance issues.

One of the biggest factors in the long-term performance of gas turbines is the lubrication it receives. Without proper lubrication, the bearing life will be greatly reduced, there will be a lot of downtimes for repairs, and the life of the unit can be greatly reduced. All recommended lubrication schedules should be followed, as well as regular inspection and maintenance. As companies like SPI Borescopes, makers of articulating borescopes, have pointed out in the past — there are many avoidable issues when proper inspection and lubrication takes place on a gas turbines.

Promoting Lubrication:

Here are the steps you need to follow to make sure a gas turbine gets the proper lubrication:

Keeping the oil clean:

Clean turbine oil is essential for maintaining the equipment and the life of the lubricant. Contamination from particulates is extremely destructive and will seriously shorten the lifespan of bearings, gears, and cause system foaming that will impact the servo-valve operation. Sources of contamination come from several places and can build up even if the oil is clean. This is another key reason operators should regularly inspect the filtration system to identify any issues.

Make sure the oil stays dry:

Water is extremely destructive to the oil’s ability to properly lubricate the components. Damaging contamination from the water will reduce the life of the turbine bearings and can cause sub-surface micro-cracking. This is something that happens over time where free radicals break off from water molecules as they pass through rollers and raceways — this leads to pitting and breaking. Centrifugal purification is the most common method of water removal, but operators sometimes use vacuum dehydration or coalescing filters, if the water concentration is low.

Maintain proper ventilation:

Obviously, oil and water don’t mix, so proper ventilation of the lubricating system will prevent condensation and help to dry water to minimize the harmful effects.

Prevent leakage when possible:

Leaking oil is wasteful and will slow productivity while the gas turbines are down for maintenance to constantly fill it back up with oil. In addition, leakage is a huge source of contamination at the seals, supply lines, cooler tube joints, and the valve connections. Too much oil pressure can lead to leaks, as well as worn seals.

Keep an eye on performance:

The quickest way to identify a problem is by ‘listening’ to what the machine is trying to tell you. Most of the time, poor lubrication that causes damages is not a problem that happens overnight. Even the slightest drop in performance should be identified as being problematic, and should not be ignored. If you not even the slightest drop in performance, you can have the company a lot of downtime and costly repairs.

Put together proper logs:

You need to log the temperatures of things like oil and water coolers and oil at different parts of the systems. A rise in temperature of oil and oil system components could indicate excessive frictions, signaling to low oil pressure, contaminates, or low oil levels. Alternatively, keeping operating records is also a vital part of identifying changes that signal to issues. Operators should note turbine and purification running times, the condition of the oil when the oil was serviced when the filter was changed, and anytime there was a replacement, repair, or rebuilding of any and all parts.

Lubrication Maintenance is a Small but Mighty Task:

Maintaining a proper lubrication system and taking action at the first sign of trouble might not seem as impactful as it is, but it’s a key business driver to companies that rely on gas turbines. This is a first-line opportunity to take preventative action and make sure your equipment is operating at world-class standards.

Read also: