A lot has been written about CMOS digital cameras. However, debates have arisen about the merits and demerits between CCD and CMOS digital cameras. The arguments continue and people have not come up with a conclusion. Nonetheless, it is not surprising that they have not come up with a definite answer since everyone has their preferences. Markets and technologies change with time influencing prices and technical feasibility. There are different imager applications, and they have different and evolving requirements. Some applications work better with CMOS imagers while some work better with CCDs, but this does not mean that one does not outperform the other.

CCD and CMOS image sensors :

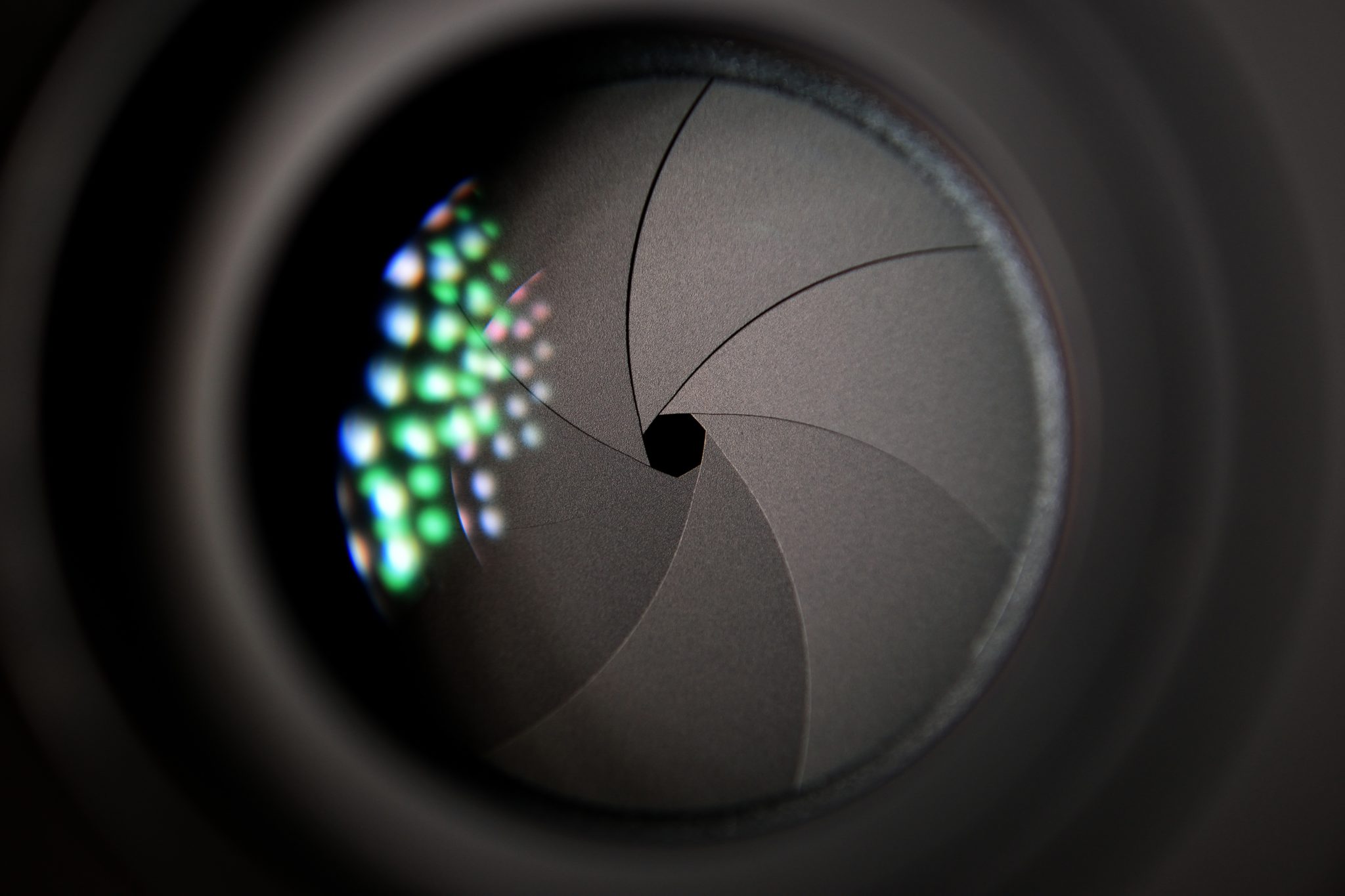

With the advent of social media, today, everyone is buying a digital camera. Every digital camera has CCD or CMOS sensor to convert light into electric signals, but even though these sensors serve the same purpose, they have some differences which affect the camera prices and the quality of the image produced. CCD (charged coupling devices) was used in pioneer cameras for image conversion from to digital pixels from analog signals of light. Due to the manufacturing process used, conversion occurs in the chip, and this reduces distortion by creating high-quality sensors that produce clear images. Nonetheless, since they need a unique manufacturing process, they end up being pricier than the CMOS.

On the other hand, to transmit a charge through traditional wires, CMOS (Complementary Metal Oxide Semiconductor) utilize transistors for each pixel. Since each pixel is treated individually, flexibility is guaranteed. The CMOS is made through traditional manufacturing processes just like creating microchips making them easier to produce and cheaper than CCD sensors. They are the reason digital cameras are more affordable.

CCD sensors are different from CMOS sensors since, with their low nose or grain, they create high-quality images. However, CMOS also create high-quality images but with high noise or grain. At the right exposure, more light is required for CMOS to produce images with low noise but CCD sensors have more elevated light sensitivity. Nonetheless, this does not imply that CMOS sensors have utmost inferiority to CCD sensors since unlike CMOS that was invented some years ago, CCD sensors have been used in digital cameras for a long time and the technology used has been advanced over the years. CMOS sensors are also gradually being advanced and they will soon catch-up and match up with CCD sensors in terms of revolution and entire quality.

With the assurance of higher integration for smaller components and lower power consumption CMOS designers focus on adapting it for the highest volume image sensor application in the world, mobile phones. Designers have invested a lot to develop and fine-tune CMOS images and manufacturing processes. Due to this investment, image quality has greatly improved, and pixel sizes have even reduced. Considering the high volume consumers and line scan imagers, CMOS imagers outperform CCDs based on almost each performance parameter imaginable.

Comparison between CMOS and CCDs :

CMOS outperform CCDs, machine noise and speed being the key parameters. Conversion of signals from single charge to analog charge and finally to analog signals is different in CCDs and CMOS. CMOS ‘data path is highly parallel in area and line sensor imagers. This causes low bandwidth in each amplifier. By the time they reach the interface between the imagers and the off-chip circuitry, the data path bottleneck, CMOS are firmly ingrained in the digital domain. Conversely, due to their high speed, the output channels in CCDs are more parallel, but they cannot match up the parallelism in COSMOS imagers. Hence, every CCD imager possesses a high bandwidth causing high noise. Nevertheless, CMOS imagers, owing to their high speed, can be designed to lower noise, unlike high-speed CCDs.

Besides the performance differences between CCD and CMOS imagers, businessmen also focus on value. It is difficult to value the cost of pictures, but leverage could be used as a great value indicator. Currently, the images in the market are cheaper than custom imagers regardless of whether they are CMOS or CCD imagers. If you need to customize the imager, compared to CMOS imagers, it is less expensive to develop custom CCD. Developing CMOS imagers is pricier because the sub-micron used are deeper and more expensive. The circuitry needed to design CMOS is also higher, and even though this makes better performing custom CMOS imagers, CCD’s value proposition is still more favorable.

Final thoughts on CCDs and CMOS :

Currently, CCD cameras have higher quality images with higher resolution but CMOS technology is being advanced day by day, and due to its longer battery life and cheaper manufacturing methods, it is bound to capture and even overtake CCD cameras. Some years to come, CMOS will become the norm of digital cameras until new technology comes up.

Read Also :