The modern era of technology has significantly transformed the traditional data management and storage system. Data security has become a crucial issue in the current data-driven world, which can’t be neglected at any cost.

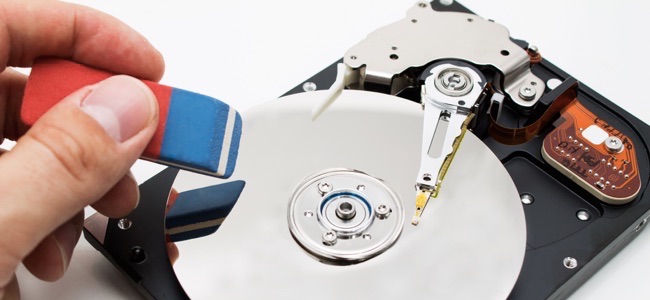

One of the significant things that people usually ignore is the importance of wiping unnecessary confidential data on their hard drives. One should ensure that their company’s crucial data is wiped properly from the hard drives so that there are no chances of a data leak.

Here we’ll discuss the importance of secure wiping of the data from your hard drive, and provide adequate information regarding the wiping process.

.

Consider a Third-Party Formatting Tool

Simple formatting of the hard drive may seem to be fruitful, but the harsh reality is; formatting doesn’t wipe the hard disk. Many of us are unaware of the fact that formatting a hard drive does not wipe a hard drive, and there are chances that your data can be recovered easily.

Sometimes people prefer formatting a portion of their hard drive to ensure permanent erasing of data. Few things must be kept in mind while formatting a hard drive and the most important thing is; one cannot simply wipe a hard drive by deleting a portion or sector of the drive.

You need to use special software that is capable of erasing the data on the hard drive permanently. You can use third-party software that is available on the internet for permanent wiping of the data from your hard disk. Furthermore, it is advised that one should prefer a renowned product, which can offer reliable performance without leaving any chance of security breach.

Steps involved in wiping the data from hard disk

Here is the step by step procedure for permanent wiping of your hard drive by using third-party software.

- First of all, back up all your necessary documents or files that you need in the future, and save them to some other drive or storage media.

- Once you are ready with the hard drive, you can download a hard drive wiping tool that can easily format the drive permanently. One can easily get freeware software from the internet. It is advised to consider paid software for the genuineness of the product.

- One should also check the configuration of the system before downloading the product to ensure compatibility

- Now install the software on your system and connect the hard drive that needs to be formatted. Ensure that you connect the drive properly in the port.

- Once you see the hard drive connected to the system, you can run the program.

- Follow the instructions on your screen, and you will be guided

- Be patient; the entire procedure takes a couple of minutes to wipe the data off your hard drive permanently.

- Once your hard drive is wiped completely, you will see a message displaying the message that the task is completed.

- Disconnect the hard drive from your computer/laptop and reconnect it to check whether the data is erased or not.

Choosing reliable software for wiping the data is essentially important from the security point of view, especially if you are involved in a business that relies on data.

Hiring Professional Data Destruction Agency

Choosing a reliable data destruction agency can be the finest way to erase the data from your hard drives permanently. The professional service providers are expert in their field and make the use of the latest software for destroying old data from the hard drive.

Furthermore, these service providers offer hard drive destruction services that can eventually leave no chances of recovering the data. Hard drive destruction involves physically destroying the hard drive by using top-notch machinery that converts your drive into pieces.

When it comes to data wiping, one should always choose a reliable service provider. Moreover, the tips mentioned above help in securely wiping your hard drives while ensuring proper security.

Read More: