If you’re unfamiliar with the spray drying process, you might be wondering what it’s used for and how exactly it works. Plus, you’ll learn about some applications you’re probably already using.

How does a spray dryer work?

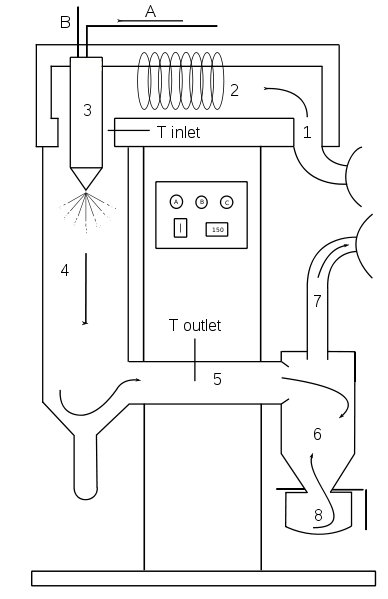

A slurry is a mixture of liquid solution and other solid materials. Companies like Elan Technology use a spray dryer to produce dry, granular powders from this mixture. This is achieved by applying the spray dryer, which uses hot air coming from a rotating wheel or nozzle to rapidly dry the slurry.

Why is it used?

In simple terms, a spray dryer is used to turn a liquid into a powder. There is a multitude of applications for spray drying that stretch across many different industries. One application that you’ve definitely seen, heard of, and likely even used before is powdered milk products.

Milk is 80% to 90% water, which means spray drying is an effective way to reduce its bulk down and make it last longer on the shelf. Using spray drying for milk products allows milk to be taken to areas where it would otherwise be unreachable.

Spray drying is also used to make whey protein supplements and countless other products, along with instant coffee and corn starch.

Outside of the food industry, it is used in the manufacturing of soap products, detergents, fertilizer, resins, and mineral ores and clays.

Is it like dehydrating?

Spray drying is similar to the traditional dehydration process (usually used for solid foods) in that it applies hot air in order to remove the water from a substance. The liquid is rapidly dried out, producing a fine powder that will later likely return to a liquid when the end-user adds backwater (like with powdered milk).

How old is the process?

Spray drying is nothing new. And although still very prevalent today, the concept of it has remained unchanged for decades. It is a patented process and is traceable back to 1872. Samuel Percy is considered to be the inventor as he was the first to describe the process. However, it was 50 years before the process was fine-tuned and finally began being used in commercial manufacturing.

While it sounds simple, it does take a bit of science to get the perfect temperature to produce a usable end powder.

A certain amount of moisture has to be removed, or the powder will be clumpy due to some water being left over.

Spray drying is a very useful technique that is in place in countless industries. Without it, people would not be able to enjoy powdered milk, instant coffee, or many kinds of detergent—like the most common dishwasher and clothing detergent products.

Samuel may have been the first to invent the process, but thousands of companies use it today. While the machines have been upgraded to work faster and produce more product, the basic concept has remained the same, and thanks to 50 years prior to fine-tuning, it always will.