Data is an important pillar of modern society. This is why many people use third-party software to encrypt data and restrict any unauthorized access. Although this might offer high-level security to the data, at the same time, it adds difficulty at the time of data recovery.

Being a digital marketer, I ensure that nobody accesses my data. To do that, I use BitLocker to encrypt all my data. One morning when I was trying to access my photos, I found that the SD card was somehow damaged, and now I cannot access my photos.

This really startled me, as it was only a couple of days away or my clients’ photos were delivered. I Tried data recovery software to recover the inaccessible photos, but the efforts were in vain, as the BitLocker was resisting to do.

Fortunately, after several tries and integrating a couple of tricks, I was able to get back my photos. It was a great feat for me, and I thought that many individuals like me face the same problem. So, I took this opportunity to share my experience and how I was able to recover data from BitLocker encrypted drives.

How to Recover BitLocker Encrypted Files?

Data recovery is a complicated and time-consuming process. There is data that can be restored or recovered from simple recycle bin recovery. The data recovery process is complex. I have come up with this solution to recover BitLocker encrypted data.

1. Recover Data from BitLocker Encrypted C: Drive:

As we know, C: Drive is the operating system drive.l the moment you start your system, new data keeps on adding to the system drive. So, the recovery of encrypted data depends on whether the lost un accessed files have been overwritten or not. In case of overwritten activity, you will not be able to get back your data. Instead, the data will stand corrupted.

However, if the data is not overwritten and is encrypted by the BitLocker, you can recover data by following the steps given below.

- Once such a scenario occurs, stop using the drives to ensure data is not overwritten.

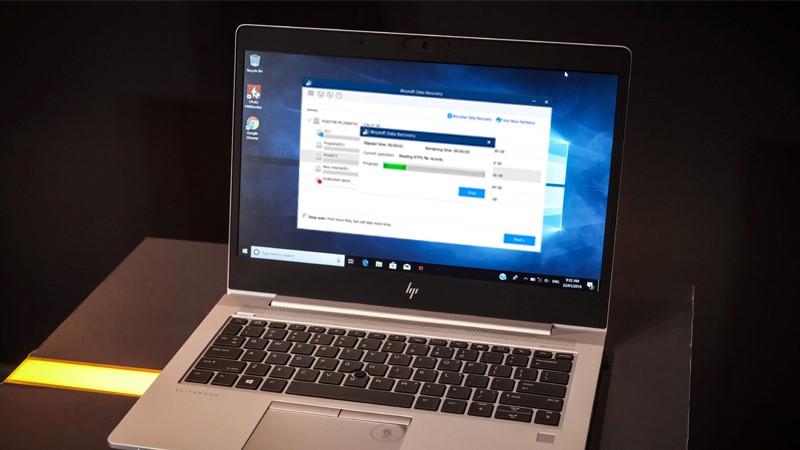

- Download a data recovery software.

- You will see the main interface with all the active drives in the system.

- Select the targeted drive.

- Initiate a scan.

- Select the data you’re meant to recover and click “Recover”.

2. Recover Data from Encrypted Data Drive:

Data drives are the drives where you store data. The D: Drive and F: drive you to see are the data drive. If you cannot access these drives, you can follow the same process. The only difference will be that you will select the drive storage instead of selecting the system storage.

- Download and install the data recovery software.

- Select the BitLocker encrypted drive.

- Run a scan.

- Select the targeted data.

- Click recover.

3. Recover Data from BitLocker Encrypted SSDs:

Today, instead of HDD, most systems have SSDs. While we use an SSD, we have no idea that it deletes data without our permission. I know this can surprise you. But that is the truth. Windows 7 or the other later ver5sion initiates an automatic TRIM on SSDs.

The only way to ensure your data is safe is to keep track of whether TRIM is enabled or not. Once you know that TRIM is Disabled, you can use the same steps to recover or access BitLocker encrypted data.

- Download and install the data recovery software.

- Select the BitLocker encrypted drive.

- Run a scan.

- Select the data you want to recover.

- Click recover.

Conclusion:

To sum it up, yes, there are easy ways in which you can recover encrypted data. In this article, I have shared the methods I used to retrieve my data. I hope that these methods work in the same way as they worked out for me.

Read Also:

- Things to Consider While Choosing Data Recovery Software

- How To Empty Trash On Android?