If you have a business, you could be making use of a commercial boiler. A commercial boiler would often be classified as such if the unit has a power rating of 70kW and above, and if your boiler unit produces this much power, then it is already categorized as a commercial boiler. You should also know that your commercial boiler needs to be regularly serviced by a professional. With regular boiler servicing, you can be sure that your property will not have any disruptions due to boiler issues, and you will not be left with more expenses in the end. But there is also a proper way to have your boiler serviced. First of all, it needs to be done by someone who is aptly qualified, such as an engineer who has a Gas Safety card. You should check that they have the right qualifications and can do commercial boiler checks and inspections. But when you have your commercial boiler serviced, here’s how a proper inspection should be done.

Step 1: a visual check:

The technician should check that the pipework of your boiler, as well as your flue and the actual boiler, are correctly installed, and they should do a visual check of both the external and internal components as well. The technician should also check for the right ventilation as well as do a visual inspection of the flame and check for any signs of leaks or corrosion. Since you are operating a commercial boiler, they should also check that it follows regulations for non-domestic property. These regulations include gas safety rules as well as building regulations, by-laws for water, and European and British standards as well.

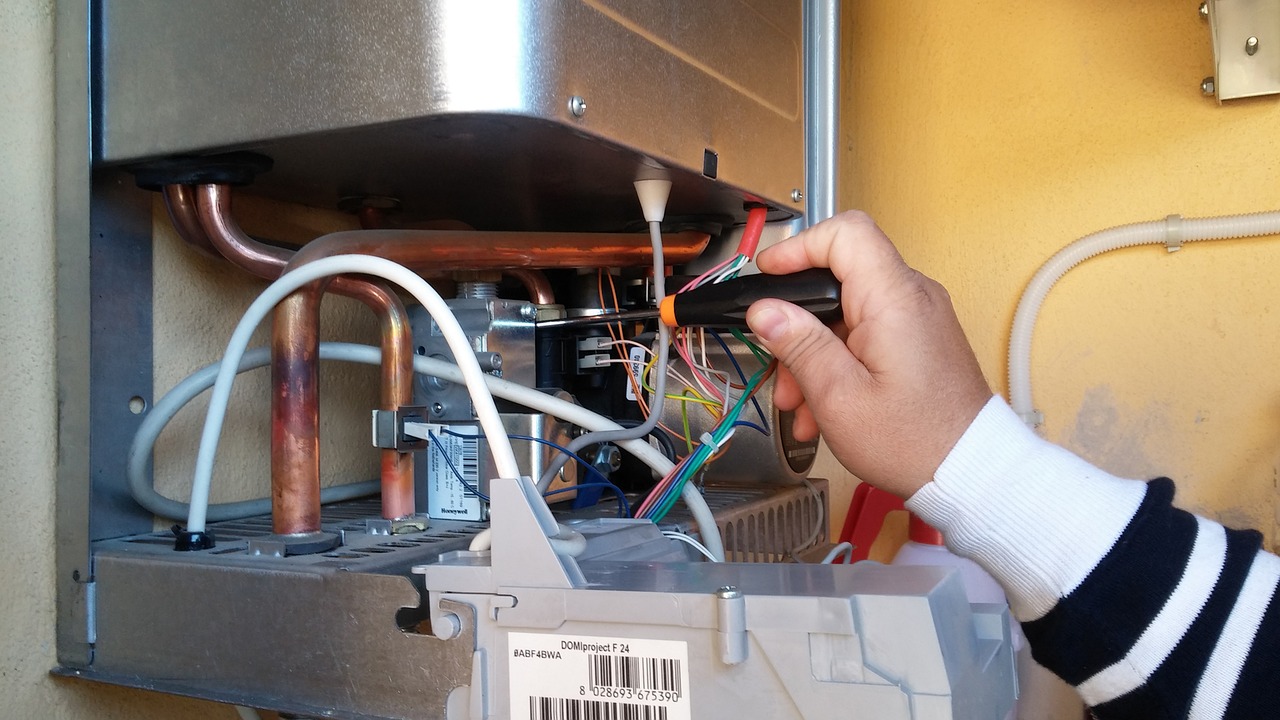

Step 2: a check of components:

The engineer or technician should then remove the casing of the boiler and inspect each internal element or component. Some parts which need to be inspected by the engineer include the gas flow and pressure, the combustion and flue, the heat exchanger, the burner, the main injector, the electrical connections, the spark probe, the seals and fans, the electrodes, the condensate pipe and trap, and the safety components or devices. After this, the engineer should clean the boiler’s insides to remove any blockage or debris.

Step 3: the tests:

The engineer should then perform tests to check that the boiler is functioning correctly according to Gas Safety regulations for installation and use. If any issues are found (e.g. gas leaks, faults, and parts which are damaged), the engineer should make a note of this in the report.

Step 4: the report:

Once they have thoroughly inspected the boiler and all its components, the engineer should give you a report of their findings and the process and checks they made, as confirmed by an experienced commercial gas engineer in north London. If there is an issue, it should also be in the report, particularly if it involves replacement or repair. If your boiler violates any regulations pertaining to Gas Safety or building regulations, the engineer should include this in the report as well.

It is essential that you ask as many questions as you can and voice any of your concerns while the gas engineer is there. This is your chance to ask for guidance and advice as well – it is, after all, your business property, and by taking advantage of a full check and inspection, you are adequately protecting your assets too.

Read Also: