Essentially, a brushless servo motor is a machine capable of developing high torques in order to oppose any effort that tries to take it out of synchronism. The name brushless comes from the simple fact that it does not have brushes and this is a way to differentiate it from other types of servomotors. Compared with other types of motors, the inertia of a brushless servo motor is substantially less. Both these characteristics – important overloads and reduced inertias – are appreciated and useful features for movement control because they allow rapid accelerations and decelerations, as well as precise position control at high speeds.

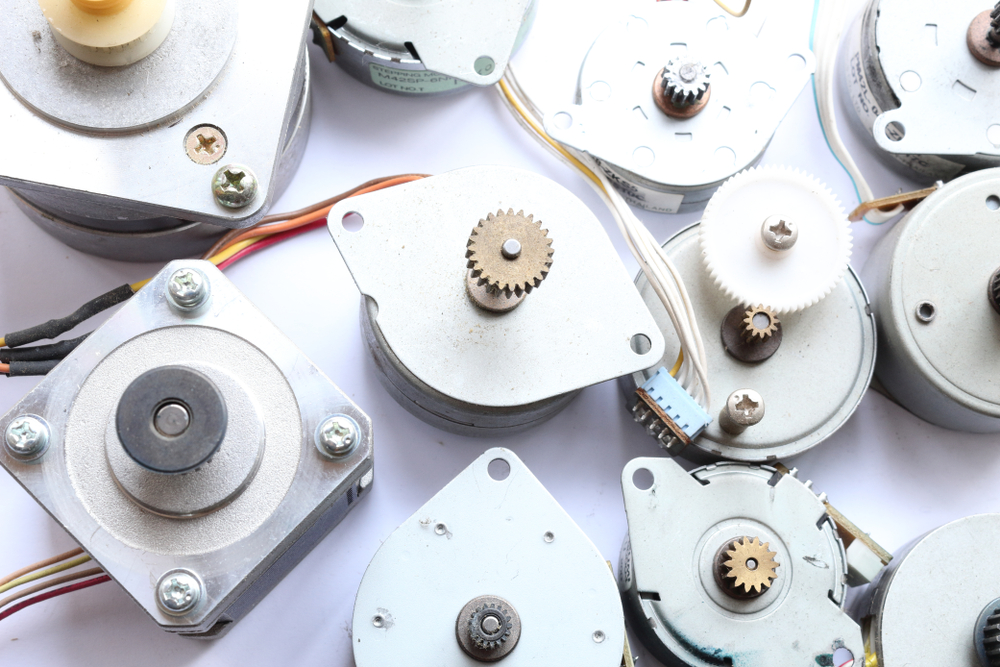

The most commonly used brushless servo motors in the industry, are those formed by a segmented stator in which the space filled with copper is almost double that in the traditional ones. This allows developing a greater power within a lower volume. Constructively, the brushless servo motor has a stator with a laminated core and a uniformly distributed three-phase winding. The rotor is constituted by a group of magnets fixed on the axis of the rotation. The shape of the rotors varies according to the design and can be cylindric or with outgoing poles.

Due to the high centrifugal forces to which they are submitted during the acceleration process, the fixing of the magnets to the rotor has been one of the critical points in the construction of brushless servo motors. This has been solved by using mechanical fixings of different types glued together using special adhesives.

In order to compensate for the greater amount of thread in the slots and its greater generation of heat, the free space of the winding is filled with heat-conducting resin. The rotor incorporates a series of permanent magnets that provide greater flow density and better performance.

The positioning time is reduced thanks to the reduction of rotor inertia that allows reaching high speeds in short times.

The Main Characteristics of this type of servo motor are:

- Performance and high torque

- Reliability of operation

- Low maintenance

- Great accuracy in speed and position control

- Very high-speed capacity

- Very low rotor losses

- Rotor with low inertia

- Closed construction, useful for working in dirty environments

- Wide range of powers (from 100 w to 300 kW)

The main advantages of the brushless servo motor are given by the possibilities that this type of motor offers in the control of its speed and positioning.

Moreover, the possibility of construction of brushless servo motors allows the adaptation of the same to diverse industrial applications. The brushless servo motors of compact structure, incorporate within it an encoder absolute which provides information on the status of the process to the controller. Those who work in a vertical position, incorporate a mechanical brake on which blocks the axis in case of lack of tension to avoid possible falls of parts in case of failure.

Inside the brushless servo motor is included as an element for the control. The encoder is formed by an electronic circuit, in which a laser diode emits a beam of light, which is interrupted by the grooves of a metal foil, giving rise to a flashing signal. Each signal, through the corresponding connector cable, arrives at the control element for processing.

Read Also: