One of the more commonly used hydraulic power packs is the mini version. This is the smaller and less powerful iteration of power packs intended for applications that don’t require the same capabilities and size provided by standard units. They can be regarded as the mid-size hydraulic units useful in different settings.

A good example of the mini-unit is the HPM mini pack. It is a good representation of the mid-size version of the standard hydraulic units. Learn about its general features, capabilities, and applications below.

Essential Things To Know About Mini Power Packs

There are several factors that you need to take care off while you want to make use of the mini power packs for your gear pump.

Features and specifications:

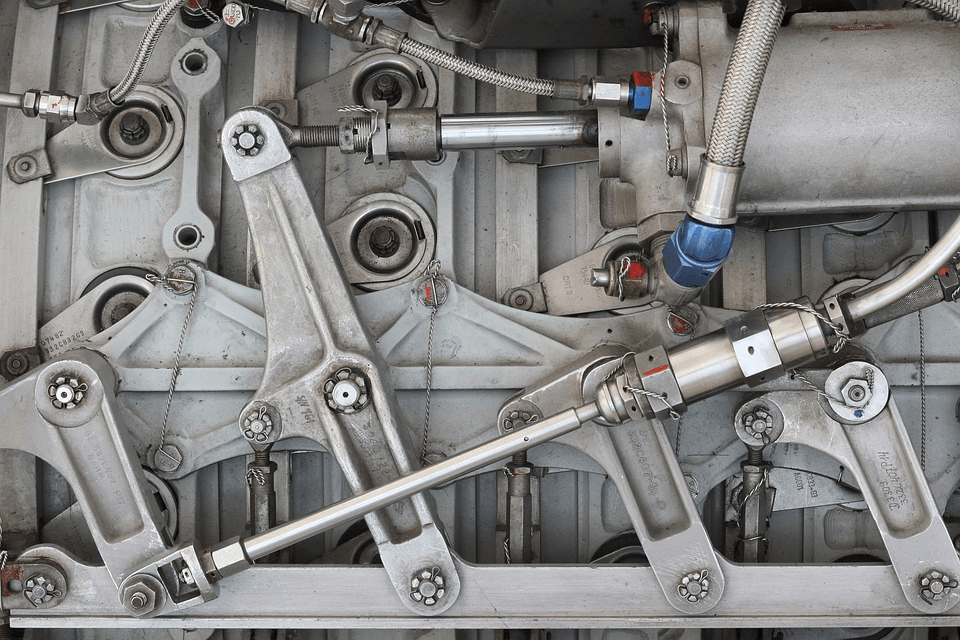

You can find many mini power packs that have an aluminium casting at the centre, which securely connects the drive motor to the gear pump. In this setup, the liquid flowing through the gear pump is directed to a relief valve, check valve, and multiple directional control valves. The pumps are driven by 12V or 24V motors with power ratings ranging from 500 watts to 3 kilowatts. The pump sizes can be from 0.25cc to 9.8cc. The tanks, on the other hand, can hold 1 litre to 55 litres of liquid.

Mini power packs can be in AC or DC variants. The AC version comes in 1 PH and 3 PH packs that are suitable for scissor lifts, dock levellers, car lifts, and the control of security barriers. They can handle a flow rate of 30 litres per minute and pressure of up to 250 bar. The DC version, on the other hand, has 12V and 24V variants with single and double acting valves. They are commonly used for stacker trucks, trailers, tailifts, and tippers.

Applications:

Mini power packs are intended for mobile, marine, and industrial applications. These include the use in security equipment, access control systems, tipping trucks, plant trailers, and scissor lifts. The mini packs are versatile enough for use in different settings. Some units equipped with 3-kilowatt 24-volt motors are commonly utilised in the ramps of plant trailers. There are those with 500-watt DC motors which are useful in the operation of step lifts. There are also light and compact power packs designed to be portable, so they can be brought to, and used, wherever they are needed.

Again, as mentioned, the details presented here are centred on the mini hydraulic power packs created by Hydra Products. Other companies may use other terms and different sets of technical specs. However, for the most part, the features and applications are similar. If you get a comparable mid-size power pack from a different company, you will likely be able to use it for the same applications.

You just need to remember that you have to scrutinise your power pack options carefully. Read the technical information to find out if what you are getting is the right unit to choose for your needs. You can consult the seller of the power pack system for guidance, or you can consult others who have the experience in using hydraulic packs, for informed insights.

Read Also: