The selection process for industrial valves is not overly complicated. However, if you’re not careful, you will end up selecting an incorrect valve. You can avoid this if you’re keen enough when it comes to choosing the right one.

However, the question is, how? How do we know if it’s the correct valve? Where should we start searching?

There are a lot of factors involved when it comes to choosing the appropriate valve for your industrial needs. Though sizing and selection can be a tedious process, understanding the requirement for applications will make it less complex.

To help you with the selection process, below are valuable details for you to take note.

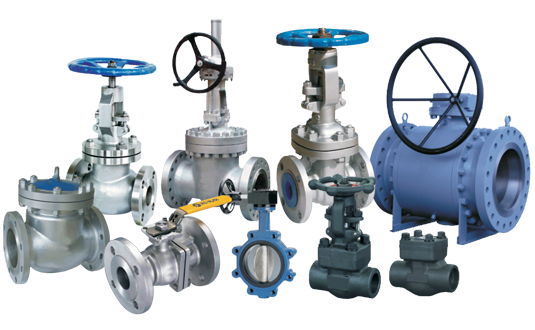

The Type of Valve:

One of the most important things you need to consider is the valve type. The type of valve needed will basically depend on the function, operation, and flow control. If flow control is needed in the process, then you will need a valve with good control performance. The size and type of a valve should be selected to support control of flow.

Those valves with plugs can be picked to change the flow of the valve. When it comes to the shutoff application, butterfly or gate valve is mostly recommended. This type offers good throttling capabilities. On the other hand, plug and ball valves are not the best options to control flow.

Moreover, if the process needs backflow prevention, then it is best to opt for a check valve. A mixing valve is an ideal choice for blending two streams process as well as water stream tempering. If the process involves feeding chemicals which are known to be a compounding process, what you need is a valve that provides the needed control capabilities.

Performance Specifications and Valve Measurement:

This is the most crucial step in choosing the appropriate valve for the application. In the event you chose an incorrect valve, it can cause issues to the valve operation within the fluid transfer system. For example, a valve that is undersized can smother the downstream flow, thus creating an upstream pressure. Valves that are oversized can only regulate a limited range of flow.

Valve operation in a nearly closed position may lead to flushing and cavitation. In the event of severe oversizing, you can pull the valve plug. This will shut off the flow. If the application needs an isolating valve, then the valve can be measured to the existing hose or pipe. Flow sizing can be a lot complicated because of the changes in flow constriction as well as the gap between the seat and the plug.

Construction of Valve Materials:

Another important factor for your valve selection process is the body materials. The environment that surrounds it, the flowing media, and maintenance are great factors that will create an impact on the valve materials. Media that are corrosive, such as saltwater, acids, chemicals, or certain food types may lead to corrosion resistant of valve materials.

If the media is a mixture of liquid with abrasive solids, then the materials’ resistant to erosion of construction are needed. It is also required to have a high strength alloy for high-pressure media to endure internal pressures. A valve with hot media will highly need an alloy that maintains durability and corrosion or oxidation resistance during an increase in temperatures.

Valve Connection and Actuation:

Put into consideration how your valve will be operated within the production. This is one important aspect should not take for granted. For manual valve operation, you need the one that has a hand wheel for manual valve opening and closing. As for an automatic valve, the one installed in a vehicle or aircraft will need an electric actuator to slide the stem. This is done through signal inputs control.

The operation of check valves is operated within the system through a pressure drop. This does not usually need any actuation process. Another selection factor to consider is the fitting type of a valve, which is often defined by the actual connections in the piping system. The connections of a valve are not considered as the fundamental criteria for selection.

Suppliers usually provide the same valve with various options for connections. Also, an adapter fitting can be purchased in the event the requested type of connection is not feasible. There are certain industries that have specific standards, regulations, and codes that are required to be followed.

Other cases, a valve must follow to these standards — NACE, API, etc. — prior using it in pressure vessel, refinery, nuclear, or other crucial applications.

Conclusion:

When selecting the right valve for your production, make sure you are packed with all the necessary details. Get to know some basic information and learn to compare each option to determine which is which. Regardless of what valve type your production needs, it is highly recommended to order from a reputable and trusted industrial valve supplier. Surely, it can get a bit complicated sometimes, but once you already have knowledge regarding what factors to consider, the selection process isn’t that hard after all.

Read Also: