Transporting liquid and gaseous substances over several kilometers has been made easy and possible by the use of pipelines. They provide a quick, safe, and effective method for conveying substances like gas, crude oil, chemicals, water, raw materials across state lines. They are also cost-effective.

Imagine having to drive any of these substances from a place like Texas to New York. While this is possible, it is expensive, dangerous, and will take days to arrive at its destination. Transporting these through pipelines helps to avoid all these.

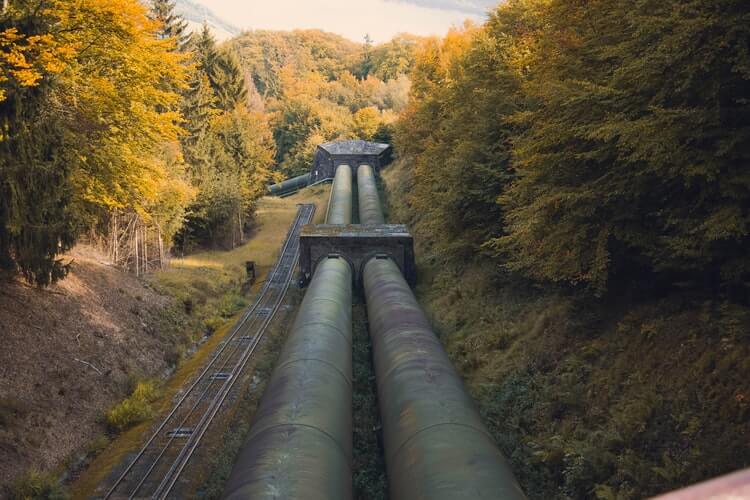

Pipelines as their name suggests are lines of pipes that are equipped with various kinds of devices like valves, pumps, etc. They are used for conveying chemical substances over long, medium, and even short distances. This is from the point of production to where these substances are needed.

Pipelines are made of materials such as metals like aluminum, steel, or cast iron. They may also be made of concrete, plastics, or clay. They come in a variety of sizes and are designed to be sectional. These sections are then bolted or welded together.

Although some pipelines are visible, most are typically buried underground and concealed from public view. This is oftentimes to ensure their safety and that of the environment. You may read more about pipeline transport here.

Pipeline Maintenance

The way they are designed means that they can withstand most weather conditions and have a long lifespan. Despite this, it is crucial to always inspect and carry out constant repairs and preventative maintenance work on them. This will ensure their integrity, reliability, and safety. It makes them safe for the environment and issues arriving from damages or failure can be avoided.

Regular maintenance also helps to comply with government regulations and avoid unnecessary downtimes which may lead to further issues. This means that any damage must be repaired immediately. Regular monitoring and maintenance will help to discover any damages early and prevent them from becoming full-blown.

While manufacturing and laying them, pipelines are checked for imperfections and they are cleared before they can be used. However, as with everything, they will go through degradation and begin to diminish gradually. They can also become corroded.

Thankfully, there are various processes available to correct these flaws and to reduce degradation. Also, when it is damaged, there are processes to carry out repairs. This is important because damages to these lines can bring about potential risks especially when the substances they convey are combustible.

Furthermore, it can affect the operations of the company, their bottom line, and the clients they serve. Therefore, it is expedient that companies that own and manage pipelines take preemptive steps to forestall any of these.

They do not have to do this by themselves as it could require a lot of resources. There are pipeline maintenance and repair companies who are experienced in doing this. They also have the resources and know-how when it comes to handling pipeline repairs.

Tips on Maintaining A Pipeline

As mentioned earlier, maintaining pipelines involves ensuring their integrity and that of all their components. This is not a one-time thing but should be done regularly. It is also important that the process be as thorough as possible.

All of these involve carefully inspecting, detecting leaks, and ensuring that the internal parts of the pipeline are clean. To this end, here are some of the ways to protect your pipeline.

1. Right of Way Clearing

One crucial aspect of maintaining a pipeline is clearing the right of way. The pipes need a clear path to travel so that they operate optimally. Right-of-way clearing involves removing trees and roots so that the area surrounding the infrastructure is free from any threat. This is also important so that the pipeline can be accessible especially during an emergency.

2. Investing in Corrosion Protection

Corrosion is one of the greatest enemies of pipelines and for this reason, it only makes sense to invest in its prevention. There are about 5 ways to do this. They include:

- Cleaning and protection. This involves pigging and using chemicals. It also includes clearing the area that is surrounding the facility.

- Cathodic protection

- Using Corrosion inhibitors

- Abrasive blasting

- Using coatings and linings

3. Hydrostatic Testing

Before you begin to use a pipeline, it is recommended that you perform hydrostatic testing. This helps to ascertain its strength. This test is also useful for measuring the strength of pipelines while in use.

Hydrostatic testing is a method where pipes to be used for a project are connected. These pipes are then filled with water at high pressure than is normal. This helps to reveal how well the pipes will perform when they are used heavily.

4. Keeping Accurate Records

It is also key that you keep accurate records each time you maintain your pipeline infrastructure. Doing so allows others to know the accurate history of the line. Part of keeping these records is taking images of the pipeline.

All of these will help in showing clearly the conditions of your infrastructure from installation. It also lets you see how fast it is corroding.

Procedures Used in Pipeline Maintenance

Pipeline repair companies have a range of procedures or methods to carry out their maintenance. They are often experienced and are able to provide you with emergency services at any time. Some of the common methods they use include:

- Hot taping

- Line stopping

- Freeze stops

- Leak repairs

- Pressure grouting, etc.

You can check out rjstacey.com – Pipeline Repair service to learn more about maintaining your pipeline.

Conclusion

Maintaining a pipeline starts from the planning stage and continues throughout its life span which can be as long as possible. It involves regularly monitoring the structure and carrying out preventive works on it. Also, when there is any form of damage, it means responding quickly to resolve this.

Experiencing downtime because of a damaged pipeline can cost a lot of money. Allowing unsafe conditions too is risky and can be debilitating to your operations in many respects. You should therefore take steps to prevent this. Start by calling in maintenance experts to help you evaluate your facility and prevent a shutdown.

Read Also:

- Highlighting the Benefits of Horizontal Directional Drilling