Are you searching for a virtual tool for disk authorization? You probably heard about the daemon tools. But when you are not sure about the security aspect of daemon tools. From file mounting to disk authorization, every piece of work is responsibly handled by the daemon tools, but the question arises ‘is daemon tools safe.’

Most of the users are using these tools to download files. And when they are asking about the security aspects of the daemon tools. The first thing that comes to our mind is whether you plan to download it from the registered sites. How safe is daemon tools? Because many users are complaining about the threats of malware and viruses after downloading the software.

Is Daemon Tools Safe?

If you are asking us this question, we would say, of course, ‘yes.’ But you only have to follow some protocols if you are thinking about the daemon tools safety issues. The first thing you must know is for what purpose the daemon tools are using.

When you want to store the CD and DVD on any hard disk, if you are going to store them as memory, it will take so much space. But daemon tools are making an optical disk image of the CD and DVD. Then you can store it on your hard disk.

This was the primary work of the daemon tools. The necessity of the Daemon tools is undeniable because, at almost 10 or 12 years of age, the CD and DVD are the only storage medium. Because Daemon tools can convert any CD storage into ISO images. And store into your desktop or laptop or send the optical images through the internet.

Is Daemon Tools Free?

When you are searching for the answer to the question, is daemon tools safe? First, take a look at the downloading security and precautions of the daemon tools. If you are downloading the software from an unknown site, the security aspect of the daemon tools is getting questioned.

If you are thinking about the security issues of your computer and desktop, always download the software files from the register sites. And always try to avoid the free version.

As with the free versions, the unknown source software sources contain viruses and malware. But when you are downloading from the sites where the authentic source and the address are present, the virus-affecting chances are reduced.

Do you think the software is now useless? From the new user’s perspective, it seems a little bit useless. But do you know that many organizations are using CDs as their storage device? For this reason, the value of the Daemon tools is remaining in the same position.

Alternatives To Daemon Tools

If the demon tool-related question ‘is daemon tools safe’ is still haunting you. And you already downloaded the software from an unknown source, and your PC is getting infected. So you want to know about the best alternative options to daemon tools.

The primary work of the demon tools is to make an iso image of the stored physical data of the disk. And make the CD data easily storable on the hard disk. Like Daemon tools, many alternatives tools are also present to perform the same work.

Check out the best daemon tools alternatives

- ISODisk.

- WinCDEmu.

- HDClone Free Edition

- Virtual CloneDrive

- WinMount.

- Microsoft Virtual CD ROM Control Panel

These all are performing the same task as the daemon tools.

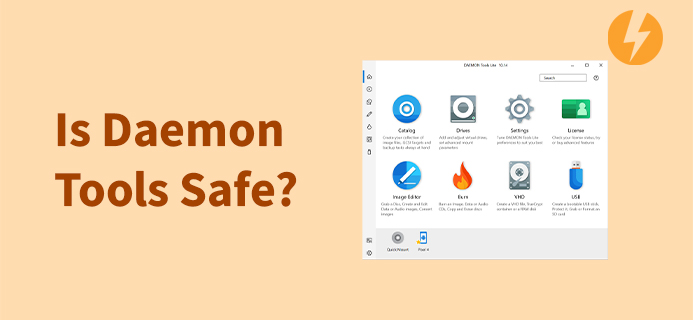

What Is Daemon Tools Lite?

Daemon tool lite is a more updated version among the Daemon tools lite. By using this tool, you can mount all types of disk image files. This tool enables you to create images of an optical disc, and the picture you can create a well-organized catalog. You can mount any type of file. And you can make MDX, MDS types files along with ISO files.

Those who are using the daemon tool lite have the same query is daemon tools lite safe. Because this is a newer version and daemon tools lite are widely downloaded by the users. Hence you can mount any type of file by using this software.

The solution is here. The answer is similar to is daemon tools safe. Do not download the software from unknown sources and unknown links. And do not go for the free user’s options. Always download the software from authentic sites.

Wrapping It Up

When you are asking about is daemon tools safe? We would say yes, the software is safe. But when you are using the authentic site to download the software, then only you are getting the virus-free software. And the paid authentic service is reducing the chances of virus attack. What are your daemon tools using experience? So do not forget to share your experiences through the comment sections.