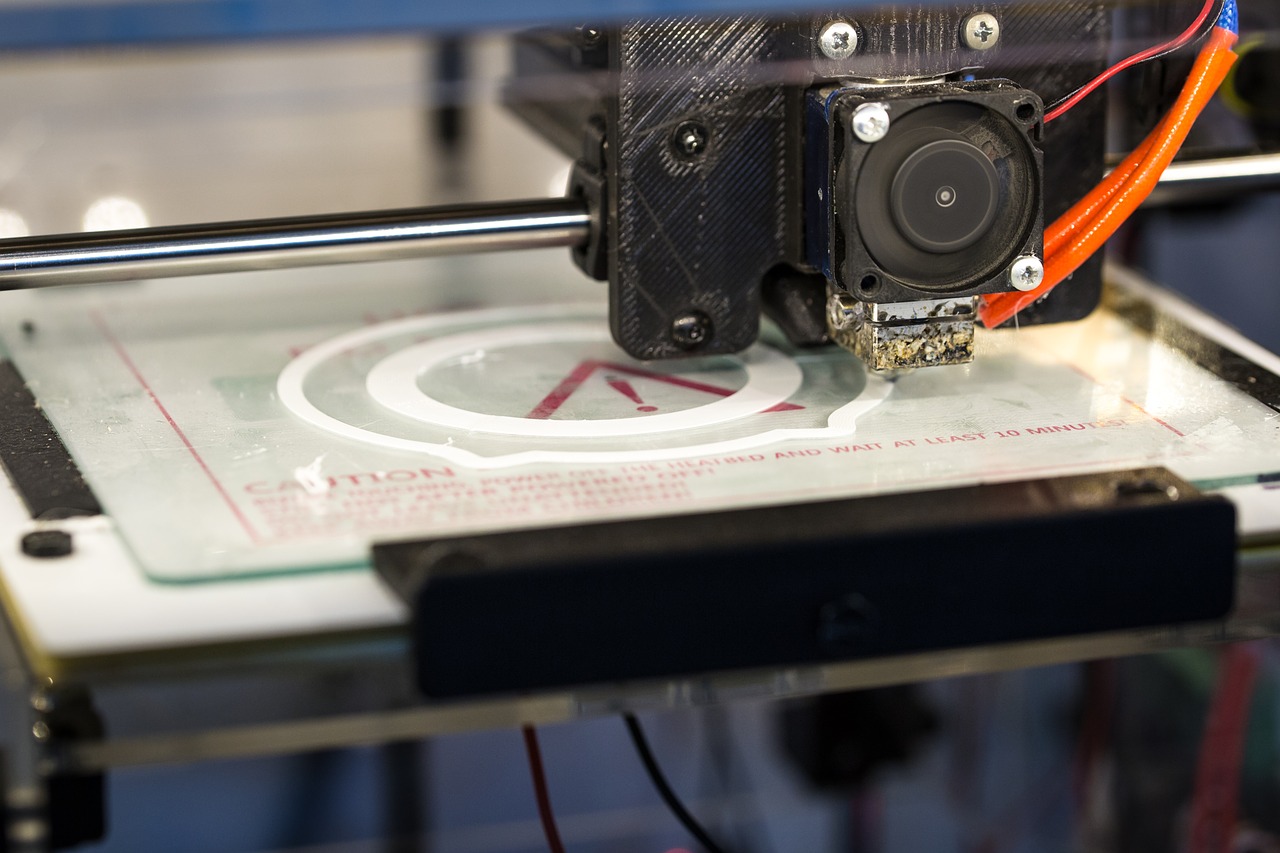

3D printing is a paradox to many with a lot of myths and misunderstandings. Many folks talk about 3D printing with so many misconceptions and false information. Dubai is leading in many areas, including technology, such as 3D printing. Although many people do not understand how this technology works, a 3D printing company Dubai specialist and other key players know the benefits.

Why 3D Printing is Popular

3D printing is not only used by inventors, but also by enthusiasts to turn their concepts into reality. Printing a model is easier and affordable compared to creating one from scratch by hand. When it comes to low quantities in production, this technology can be used to create and test products. This process can be done severally, cost less, and produce effective goods compared to the conventional way.

Printing from home or seeking a 3D printing company Dubai specialists keeps your designs private, reducing the possibility of imitation. Likewise, you can share your designs with an online community and interact with like-minded individuals.

Apart from printing models, 3D printers can print end products ready for the market. In today’s world with mass manufacturing, things like tailor-made toys are expensive; however, 3D printing solves this problem.

3D Printing Myths

3D printing has been around for over a decade, but most folks still hold on to their myths about this great technology. The misconceptions are both positive and negative.

Below are the biggest myths about 3D printing:

1. 3D Printing is Expensive

Many people believe that 3D printing is not only expensive but agonizingly slow. However, this was true in the previous years, where you needed expensive equipment and materials. You also used the tiresome trial-and-error method to improve the designs.

This changed when a variety of new methods were introduced. These techniques allow any 3D printing company Dubai specialists to improve their products. You can also print in minutes, and the printers are cost-effective. The prices continue to fall as the manufacturers use cheaper but effective materials.

2. You Can Only Print Small Products

Any 3D printing company Dubai specialist will tell you that a 3D printer is not large. They are made this way because they need an airtight chamber to work. Most folks believe that printing in bulk would be a waste of time, while others claim that plastic filament cannot make strong products. However, methods, such as Big Area Additive manufacturing, function in the open air, and produce sturdy pieces. They are used to create a wide range of products from jet fighters to automobiles. Recently, the printer bot has been used to rapidly add fast-hardening materials in the construction industry.

3. 3D Printing Results in Poor-Quality Products

The most laborious process of creating a 3D product is ensuring that the result looks good. A common myth that many people stand by is that you cannot print quality goods using this technology. However, some new methods like Digital Light Synthesis help generate elaborate products from the start. The high-quality finish happens because the process does not require layering. The outcomes are monolithic meaning that they come out as a smooth liquid. Other people also combine hybrid systems that used 3D printed goods with traditional finishes.

4. 3D Printing Can Make Artificial Organs

Bioprinting is an exciting element in additive manufacturing. Many patients wait eagerly waiting for 3D printed kidneys, hearts, and other vital organs. Today, any 3D printing company Dubai specialists can easily customize orthodontics, prosthetics, and hearing aids. Some people believe that with the advancement in technology and especially in 3D printing, we could develop organs very soon. However, scientists are yet to discover how to create such sophisticated items. We can create a network that can support muscles and living tissues; however, we cannot create the tissue itself.

5. Small-Scale Players will Dominate the Market

Some folks believe that 3d printing would usher in a new era of people using this technology to produce small quantities for their use at home. In reality, only a few folks own 3D printers. Educational institutions and corporations own the majority of these machines, and this might not change any time soon.

3D printing might bring an era where manufacturers benefit more from this technology when compared to civilians. This technology can help industries to create a different product every month depending on consumers’ demands. This way, companies can reap more by specializing in a wide variety of products. Eventually, the market will get a new wave of diverse industrial giants that cater to different customers.

3D printing might be new to some, and it might be complicated to others. Although the art of 3D printing has been around for over a decade, some folks still believe myths. Creating vital organs such as hearts and other internal organs is only a myths. It is important to get information from specialists to avoid misinformation.

Read Also: