How to cancel Walmart plus subscription? If this is something that you have been searching for, then you have reached the right place.

What Is Walmart Plus?

Answering the question, “how to cancel Walmart plus?”

Want to know how to unsubscribe from Walmart Plus?

I will teach you the following ways to cancel your Walmart subscription.

- How to cancel Walmart Plus online via a web browser

- How to cancel Walmart Plus on app

- How to cancel Walmart Plus account by phone

How To Cancel Walmart Plus Membership Online Via a Web Browser?

Here’s how to cancel Walmart Plus account online using your web browser.

- Go to the Walmart website and log in to your account.

- Click your name in the top-right corner.

- Select Walmart+ from the dropdown menu.

- Click Manage membership.

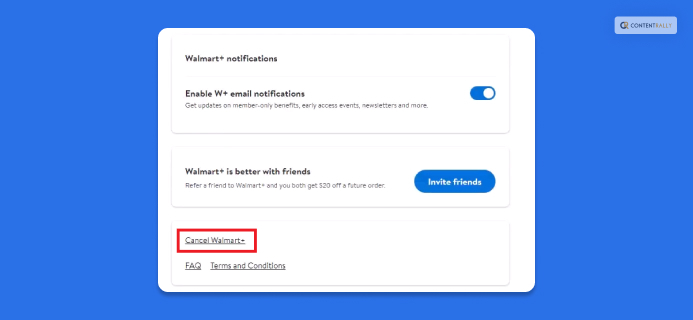

- Click Cancel Walmart+ at the bottom of the page.

An easy tip during your free trial period is to wait until the last day to cancel your Walmart membership. The site may offer you an additional 15 days before confirming your cancellation.

If you want to extend your membership, choose the Extend free trial option. If not, choose the Cancel free trial option.

Remember, Walmart will charge your credit or debit card for the membership cost if you don’t cancel your free trial before it ends.

How To Cancel Walmart Subscription On App?

Here’s how to cancel a Walmart subscription on the mobile app.

- Open the Walmart app on your mobile device and log in to your account.

- Tap Pickup and Delivery on the home screen.

- Click the menu icon (the three lines) at the top-left corner of your screen.

- Choose Walmart+ under Pickups and Deliveries on the window that pops up.

- Your account information will appear. Tap Cancel Walmart+ Trial or Account at the bottom of the page.

After confirming your cancellation, Walmart will notify you that you’re no longer a Walmart+ member. You can continue using your benefits until your current pay cycle ends.

Walmart won’t charge you after your Walmart+ account expires, but you can no longer access the benefits of the membership program or subscription service.

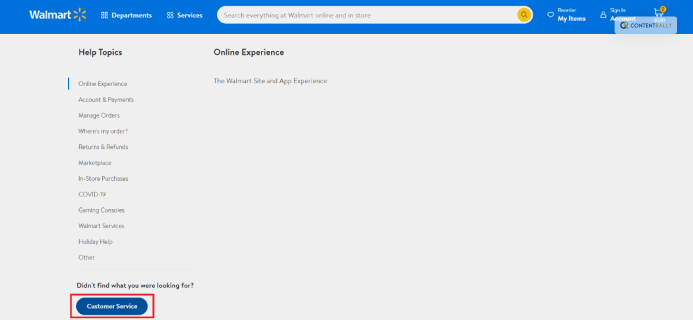

How To Cancel Walmart Plus Free Trial Period By Phone?

You can cancel your Walmart Plus free trial or paid membership by calling Walmart Customer Care at (800) 924-9206, available daily from 8 AM to 10 PM CST.

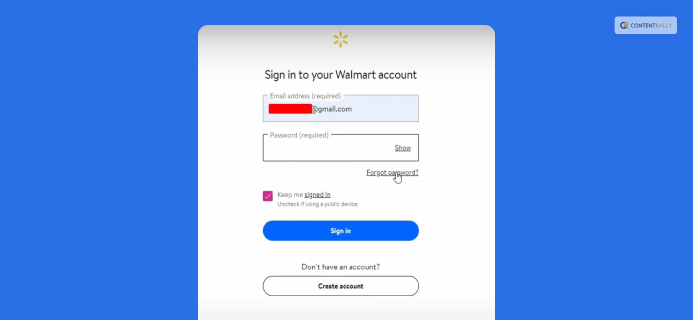

How to Login To Walmart Plus?

In case you want to log in to Walmart Plus, it is important that you follow these steps.

- Visit the Walmart Plus website on your browser.

- Click on Start your free 30-day trial.

- Enter your email address and click on Continue.

- Enter your name and password while signing up and click on Create Account to get some promotional discounts.

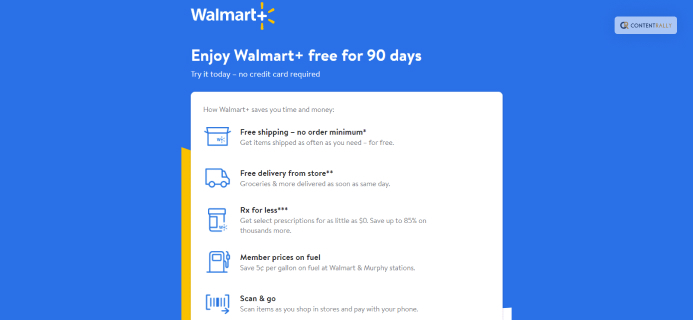

Does Wamart Have A Free Trail?

How To Cancel A Walmart Plus Free Trial?

If you are in your trial phase in Walmart plus here are the steps that will help you achieve yours.

1. Navigate to the Walmart website.

2. From the top right corner, click on Hi, [your name] Account.

3. Click on Account from the drop-down menu.

4. From the left pane, click on Walmart+.

5. Select Manage membership.

6. Over the bottom you will have a Cancel Free Trial.

Can You Cancel Walmart Plus Subscription Anytime You Want?

A lot of us like to try out a few things but then want to cancel these subscriptions. The Walmart Plus subscription is no less different than that.

Your Plus subscription can be canceled at any time. Depending on your preference, you can cancel it right away or wait until the end of your pay cycle.

You will not receive a refund for the remaining days if you cancel during the middle of a billing cycle. Consequently, you must plan your cancellation accordingly.

Benefits of A Walmart Plus Subscription

Walmart Plus is close to the top of the list when it comes to perks for subscription services offered by retailers. Customers benefit greatly from it, especially if Walmart is your primary retailer.

Six months of Spotify Premium for free are one of the first benefits you receive. That amounts to a value of $59, which is more than half the annual cost of a Walmart Plus subscription. Video streaming is also included through the Essential plan of Paramount Plus. That is a great deal of diversion stacked on top of the typical advantages. Another advantage is free conveyance from your nearby Walmart store, gave your request is somewhere around $35. You must reserve a time in advance due to some restrictions. With the exception of oversized and Marketplace items, you can also get free shipping. This also includes delivery the same day or the next; ideal for customers who primarily use Walmart for grocery delivery.

Wrapping It Up!

In case you were searching for the answer to how to cancel Walmart Plus, I hope that this article has been of help to you. If there are any other queries related to the same, feel free to let me know. All that you need to do is scroll down till you reach the bottom of the page. Then leave your suggestions and doubts in the comment box below how to cancel walmart plus? – Step by step guide.

Read Also: